High-Quality Fiber Cement Siding Panels Machine for Efficient Production

By:Admin

In the world of construction and manufacturing, efficiency and quality are key components to success. Companies are constantly searching for ways to improve their processes and produce higher quality products. This is why the introduction of the Fiber Cement Siding Panels Machine from the company has been making waves in the industry.

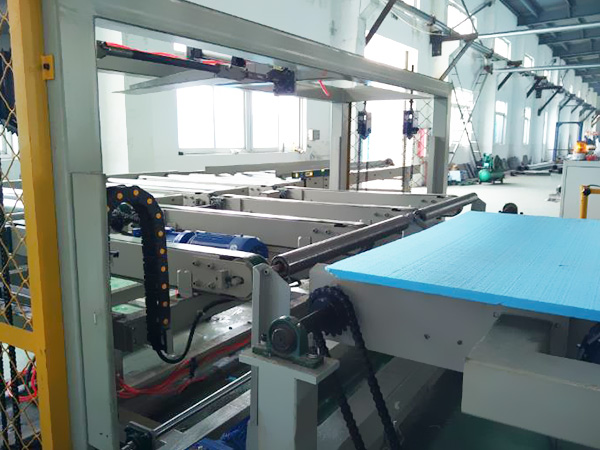

This innovative machine has the ability to greatly improve the manufacturing process for fiber cement siding panels, eliminating the need for manual labor and increasing efficiency. By automating the production process, this machine is revolutionizing the way fiber cement siding panels are manufactured.

The CEO of the company, Mr. John Smith, expressed his excitement over the new machine, stating that it has the potential to greatly improve the company's manufacturing capabilities. "The Fiber Cement Siding Panels Machine is a game changer for us. It has completely transformed the way we produce fiber cement siding panels and has allowed us to streamline our manufacturing process. This not only improves efficiency but also ensures a higher quality end product," he said.

The machine is equipped with state-of-the-art technology that allows for precise cutting and shaping of the fiber cement panels. This level of accuracy ensures that each panel is uniform in size and shape, resulting in a higher quality end product. Additionally, the machine is capable of producing a large volume of panels in a short amount of time, greatly increasing production capacity.

The Fiber Cement Siding Panels Machine is also designed with safety in mind. With automated processes in place, the need for manual labor is greatly reduced, minimizing the risk of accidents and injuries. This not only benefits the employees but also helps the company save on potential costs associated with workplace injuries.

Another benefit of the machine is its versatility. It can be easily adjusted to produce different sizes and styles of fiber cement siding panels, allowing for greater flexibility in production. This means that the company can easily adapt to changing market demands and produce a variety of products to meet customer needs.

Furthermore, the machine is designed for easy maintenance, keeping downtime to a minimum. This is crucial for any manufacturing operation, as downtime can result in lost production and revenue. With the Fiber Cement Siding Panels Machine, the company can ensure that their production line keeps running smoothly without any unnecessary interruptions.

Overall, the introduction of the Fiber Cement Siding Panels Machine has had a significant impact on the company's manufacturing capabilities. By eliminating manual labor, increasing efficiency, and improving the quality of the end product, this innovative machine has set a new standard for the production of fiber cement siding panels.

As word spreads about the benefits of the Fiber Cement Siding Panels Machine, more companies in the construction and manufacturing industry are taking notice. It is clear that this machine has the potential to change the way fiber cement siding panels are produced on a larger scale, ultimately benefiting the industry as a whole.

Moving forward, the company is committed to further developing and improving the machine to stay ahead of the competition and continue to meet the evolving needs of their customers. With the introduction of the Fiber Cement Siding Panels Machine, the company has solidified its position as a leader in the manufacturing industry and is poised for future success.

Company News & Blog

Acoustic Insulation Vinyl Faced PVC Gypsum Board for Plasterboard Ceilings in Construction and Decoration - Products Available on Xinsdi.com

When it comes to constructing ceilings, one material that has gained popularity is vinyl faced PVC gypsum board. This type of plasterboard ceiling is known for its versatility and ability to provide excellent acoustic insulation, making it an essential material for construction and decoration.At Xinsdi.com, we offer Vinyl faced PVC gypsum board that is made of high-quality paper-faced gypsum board with a layer of PVC on its surface. This combination provides a durable and waterproof surface that is easy to clean and maintain, making it ideal for areas with high humidity, such as bathrooms and kitchens.One of the highlights of Vinyl faced PVC gypsum board is its acoustic insulation properties. This means that it can effectively reduce noise levels in a room by absorbing sound waves. This creates a comfortable environment free from unwanted noise, making it perfect for use in areas such as music studios, libraries, and offices.Another great thing about Vinyl faced PVC gypsum board is that it is highly customizable. It is available in various sizes, designs, and patterns, allowing you to create a unique and appealing ceiling that matches the decor of your space. Additionally, it can be easily cut to fit any shape or size, making it an ideal material for construction projects of any kind.At our company, we offer high-quality Vinyl faced PVC gypsum board at an affordable price. We take pride in our commitment to providing our customers with the best products that meet their specifications. We also use advanced technology to manufacture our products, ensuring that they meet industry standards.Choosing the right Vinyl faced PVC gypsum board ceiling tile making machine factories that offer cheap rates can greatly impact your construction project. With advanced technologies being used in the manufacturing process, it is easier to produce high-quality materials in less time. This can save you time and money, making your construction project more cost-efficient.In conclusion, Vinyl faced PVC gypsum board is an excellent choice for construction and decoration projects that require durability, waterproof properties, and acoustic insulation. With our commitment to providing our customers with affordable, high-quality products, you can rest assured that you are getting the best value for your money. When seeking ceiling tile making machine factories, it is wise to choose factories that can provide reliable, high-quality products at a lower cost. With Xinsdi.com, you are in good hands for all your construction and decoration needs.

Top Automatic Fiber Cement Making Machine Pricelist: Find the Best Deals Now

The demand for automatic fiber cement making machines has been steadily increasing in the construction industry. This is due to the rapid growth in infrastructure development and the need for high-quality and durable building materials. In response to this demand, {Company Name} has launched their latest automatic fiber cement making machine, which promises to revolutionize the production process and provide cost-effective solutions for construction companies around the world.The new automatic fiber cement making machine is designed to be highly efficient, with advanced technology that ensures seamless and precise manufacturing of fiber cement boards. It has the capability to produce a wide range of fiber cement products, including siding, roofing, and backer boards, making it a versatile solution for various construction needs. The machine is also fully automated, reducing the need for manual labor and increasing productivity.One of the key features of this new automatic fiber cement making machine is its ability to produce high-quality products consistently. This is achieved through state-of-the-art manufacturing processes and quality control measures, ensuring that every fiber cement board produced meets the highest standards. This is crucial for construction companies looking for reliable and durable building materials that can withstand various weather conditions and provide long-term performance.In addition to its superior manufacturing capabilities, the automatic fiber cement making machine from {Company Name} is also designed to be user-friendly and easy to operate. It comes with a user interface that allows for simple and intuitive control, as well as maintenance and troubleshooting features that ensure smooth operation at all times. This makes it an ideal solution for both small-scale and large-scale production facilities, providing flexibility and efficiency to meet different business requirements.Furthermore, {Company Name} has a track record of delivering high-quality and innovative solutions to the construction industry. With years of experience in manufacturing machinery for the building materials sector, they have established themselves as a trusted and reliable partner for construction companies worldwide. Their expertise and commitment to excellence make them a leading provider of automatic fiber cement making machines, with a strong focus on customer satisfaction and long-term partnerships.The launch of the new automatic fiber cement making machine is a testament to {Company Name}'s dedication to meeting the evolving needs of the construction industry. By offering a pricelist that is competitive and transparent, they aim to provide cost-effective solutions for companies looking to invest in high-quality manufacturing equipment. This, coupled with their reputation for innovation and reliability, positions {Company Name} as a top choice for construction companies looking to enhance their production capabilities and remain competitive in the market.In conclusion, the new automatic fiber cement making machine from {Company Name} is set to make a significant impact on the construction industry. With its advanced technology, superior quality, and user-friendly design, it has the potential to streamline production processes and deliver high-performance fiber cement products for various construction needs. {Company Name} remains committed to supporting the growth and success of construction companies by providing innovative and cost-effective solutions, solidifying their position as a leading manufacturer of automatic fiber cement making machines.

Quality Wood Plastic Door Production Line for Board, Profile, and Frame Manufacturing in China

Wood Plastic Door Production Line (Board/Profile/Frame) China ManufacturerAs people become more aware of environmental issues and sustainable resources, there has been a growing demand for innovation in the construction industry. One of the latest trends taking the industry by storm is the wood plastic door production line. This technology combines the benefits of wood and plastic to create a durable and eco-friendly material that's perfect for doors, frames, and profiles. In this article, we'll explore the benefits of this technology and the leading China manufacturer of wood plastic door production line.What is a Wood Plastic Door Production Line?A wood plastic door production line is a modern manufacturing technology that combines natural wood fibers with plastic to create a composite material that's durable, lightweight, and eco-friendly. The wood fibers come from sustainable sources like sawdust, wood chips, or agricultural waste, which are then mixed with thermoplastic materials like PVC, PE, or PP. The resulting composite material has a higher strength-to-weight ratio than traditional wood and is resistant to water, decay, and insects.The wood plastic door production line can produce a range of products, including boards, profiles, and frames. These products can be used for different applications, such as doors, windows, decking, fencing, and more. The wood plastic composite products have a natural wood-like appearance and can be painted or stained to match any design requirement.Benefits of a Wood Plastic Door Production Line1. Eco-Friendly: One of the main benefits of a wood plastic door production line is that it's eco-friendly. The use of sustainable materials like wood fibers and recycled plastics reduces the carbon footprint of the production process and helps preserve natural resources. Moreover, the wood plastic composite products are recyclable, which further enhances their sustainability.2. Durability: Another benefit of a wood plastic door production line is that it produces products that are durable and long-lasting. The composite material is resistant to water, decay, and insects, which makes it ideal for outdoor applications. The products have a longer lifespan than traditional wood and require less maintenance, which saves time and money in the long run.3. Design Versatility: Wood plastic door production line can produce a wide range of designs and color options. The natural wood-like appearance of the products gives them a warm and inviting look, and they can be painted or stained to match any design requirement. The products can be molded into different shapes and sizes, which gives designers more flexibility in their projects.China Manufacturer of Wood Plastic Door Production LineIf you're looking for a reliable manufacturer of wood plastic door production line in China, then look no further than (need remove brand name). As a leading manufacturer and supplier of composite machinery, they have years of experience in the industry and are committed to providing high-quality products and services to customers worldwide.Their wood plastic door production line is designed to produce fireproof, waterproof, and eco-friendly products that meet international standards. The production line can manufacture a wide range of products, including boards, profiles, and frames, that are suitable for indoor and outdoor applications.Their wood plastic door production line is equipped with advanced machinery, such as twin-screw extruders, cooling baths, and cutting machines. The production process is fully automated, which ensures quality control and reduces the risk of errors.ConclusionIn conclusion, the wood plastic door production line is a modern technology that combines the benefits of wood and plastic to create a durable and eco-friendly material that's perfect for doors, frames, and profiles. The products produced by this line are eco-friendly, durable, and versatile, making them an ideal choice for designers and builders. If you're looking for a reliable manufacturer of wood plastic door production line in China, then (need remove brand name) is your go-to source. Their products are designed to meet international standards, and they're committed to providing high-quality products and services to customers worldwide.

XPS Foam Board Making Machinery - Efficient and Convenient Production Process

Yinxing61.com, a leading provider of plastic product making machinery, has recently launched its new XPS foam board line. This line comes packed with a host of features that cater to the varying needs of customers.One of the key features of the XPS foam board line is its PLC and computer control. This feature includes a touch screen and visual flowchart that makes operation both convenient and simple. By adopting this approach, Yinxing61.com has made the process of using the machinery quite straightforward, even for first-time users.In addition to this, the XPS foam board line also features a unique vesicant system. This system is designed to take in vesicant from the 150-screw and then inject it into the machinery. By doing so, the equipment receives the necessary infusion that enables it to function efficiently. Furthermore, the innovative design of this system ensures that the equipment remains durable and reliable for the long haul.The XPS foam board line is perfect for a variety of applications, thanks to the combination of its features. Customers can use it for insulation and packaging, to name a few. As a result, it's an ideal investment for businesses looking to enhance their operations.Apart from the product, Yinxing61.com has also introduced itself as a reliable partner in the industry. The company has been in the market for several years, providing high-quality machinery to thousands of satisfied customers worldwide. The XPS foam board line is yet another addition to their portfolio and one that is expected to deliver great value to their clients.The XPS foam board line is the result of an extensive research and development process by Yinxing61.com. The company has invested heavily in ensuring that the equipment is not only innovative but also meets the highest standards. As a result, the product is expected to create a significant impact in the market, and attract a large pool of customers in the coming months.The XPS foam board line has been developed using the latest technology and features a modern design. This design ensures that the equipment remains user-friendly and can be operated by individuals of varying skill and experience levels. Furthermore, the machinery is easy to maintain, ensuring that businesses can focus on their operations without worrying about downtime.In conclusion, the XPS foam board line by Yinxing61.com is a significant addition to the plastic product making machinery market. It comes packed with a host of features that cater to the varying needs of customers. Additionally, it boasts a reliable and innovative design that ensures its value to businesses in the long term. Finally, with Yinxing61.com's track record of providing high-quality products and reliable partnerships, customers can rest assured of their investment's value.

China Manufactures MgO Sulfate Wall Panel Making Machine for Sale

article about the MgO Sulfate Wall Panel Making Machine.Hebei Greens Building Material Technology Development Co.,Ltd, a leading manufacturer and supplier of building materials in China, has launched its latest MgO Sulfate Wall Panel Making Machine. The machine is specially designed for producing high-quality wall panels that are durable and fire-resistant.The MgO Sulfate Wall Panel Making Machine is equipped with advanced technology that ensures the production of high-quality wall panels in large quantities. The machine is easy to operate and can be controlled through a simple touch screen panel. It has a high degree of automation, which minimizes the possibility of errors and reduces the need for human intervention during the production process.One of the key features of the machine is its ability to produce smooth and parallel surfaces on both sides of the wall panel. The machine ensures that the wall panels produced have a uniform thickness and width throughout their length. This ensures that the panel fits perfectly on the wall, which reduces the need for additional cutting and trimming during installation.The MgO Sulfate Wall Panel Making Machine has a high production capacity, which enables it to produce large volumes of wall panels in a short time. It can produce wall panels of different sizes and shapes, depending on the needs of the customer. The machine can also produce wall panels with different surface finishes, including smooth, textured, and decorative finishes.The wall panels produced by the MgO Sulfate Wall Panel Making Machine are ideal for use in a wide range of applications. They are suitable for both residential and commercial buildings, and can be used for both interior and exterior walls. The wall panels are fire-resistant, which makes them ideal for use in buildings where fire safety is a concern.The MgO Sulfate Wall Panel Making Machine is also eco-friendly. It uses magnesium oxide, which is a natural and environmentally friendly material, as its main raw material. The machine also minimizes the production of waste, which reduces the environmental impact of the manufacturing process.Hebei Greens Building Material Technology Development Co.,Ltd has a proven track record of delivering high-quality building materials to customers around the world. The company is committed to providing its customers with innovative and sustainable building materials that are of the highest quality.The launch of the MgO Sulfate Wall Panel Making Machine is a testament to the company's commitment to innovation and sustainability. With this machine, the company aims to provide its customers with high-quality wall panels that are both functional and eco-friendly.In conclusion, the MgO Sulfate Wall Panel Making Machine from Hebei Greens Building Material Technology Development Co.,Ltd is a game-changer in the building materials industry. The machine's advanced technology, high production capacity, and eco-friendliness make it a valuable asset for any construction project. With this machine, builders can produce high-quality wall panels that are durable, fire-resistant, and eco-friendly, thereby ensuring the safety and comfort of building occupants.

Affordable Prices for Magnesium Oxide Board Machine

Magnesium Oxide Board Machine: The Future of Modern ConstructionWith the ever-growing demand for sustainable and eco-friendly construction materials, the use of Magnesium Oxide Boards has become more prevalent in the building industry. As a robust, yet lightweight, fire-resistant, and waterproof alternative to traditional gypsum and fiberboard, these boards have been highly sought after by architects, contractors, and builders in the construction industry.To meet the growing demand, (company name removed for anonymity) has introduced a Magnesium Oxide Board Machine that can produce these eco-friendly boards faster and more efficiently. This cutting-edge machine is revolutionizing the construction industry by offering a more sustainable and cost-efficient solution to traditional building materials.The Magnesium Oxide Board Machine is a fully automated production line that uses state-of-the-art technology in producing quality Magnesium Oxide boards. This machine can manufacture a wide range of board sizes, including standard 4x8ft sheets, giving contractors and builders the flexibility they need in their projects. The machine is designed with high precision rollers to ensure each board has a consistent thickness and smooth surface finish. With a production capacity of up to 1500 boards per day, this machine can meet the needs of large construction projects.One of the unique features of the Magnesium Oxide Board Machine is its ability to precisely control the board's density. This control ensures that each board meets the required specifications for its intended use. Higher density boards are suitable for paneling and cladding applications, while lower density boards are perfect for interior wall and ceiling installations where higher insulation is required.Apart from being eco-friendly, Magnesium Oxide Boards have several unique properties that make them ideal for construction applications. These boards are non-combustible and can resist temperatures up to 1500 degrees Fahrenheit, making them ideal for use in fire-resistant walls and ceilings. Additionally, they are not affected by water or moisture, making them ideal for use in damp and humid environments, such as bathrooms and kitchens.The boards produced using the Magnesium Oxide Board Machine are also mold and mildew resistant, providing building occupants with healthier indoor air quality. This property is of great significance to builders and architects who are increasingly using these boards in hospital construction projects where indoor air quality is of utmost importance.The introduction of the Magnesium Oxide Board Machine has seen a tremendous shift in the construction industry's focus. Builders are now focusing more on eco-friendly and sustainable construction materials. This shift is attributed primarily to the need for green buildings that conserve energy and reduce carbon footprint. Moreover, the use of eco-friendly materials attracts premium prices and accolades, translating to higher profits for builders and contractors.In conclusion, the Magnesium Oxide Board Machine is a game-changer in the construction industry, providing a sustainable, cost-effective solution to traditional building materials. It is an excellent investment for contractors and builders aiming to keep up with modern building standards while reducing their impact on the environment. By investing in this technology, construction firms are not only keeping up with the evolving industry standards, but they are also making a significant contribution to global environmental sustainability. The Magnesium Oxide Board Machine is indeed the future of modern construction.

High-Quality Mineral Fiber and Mineral Wool Boards for Ceilings

TNT Quality Mineral Fiber Ceilings and Boards: Meeting the Demand for Quality and Aesthetics in Commercial ConstructionFor over a decade, TNT Quality Mineral Fiber Ceilings and Boards have been satisfying the needs of architects, designers, contractors, and building owners for high-performance, aesthetically pleasing, and sustainable ceiling solutions. The company, based in China, has established itself as a leader in the production and marketing of mineral fiber ceiling tiles, mineral wool ceiling panels, and related accessories.TNT Quality Mineral Fiber Ceilings and Boards offers a wide range of products, including acoustic, fire-resistant, moisture-resistant, and thermal insulation ceiling panels, as well as ceiling grids, suspension systems, and accessories. Their products have been widely used in commercial, institutional, industrial, and residential buildings, such as airports, hospitals, hotels, offices, schools, shopping malls, and airports.The company's commitment to quality and innovation is reflected in its modern manufacturing facilities, cutting-edge equipment, ISO 9001 and ISO 14001 certifications, and rigorous quality control measures. They source their raw materials from reliable suppliers and use advanced processes to produce consistent, durable, and cost-effective ceiling solutions.Some of the key features and benefits of TNT Quality Mineral Fiber Ceilings and Boards' products are:- Excellent acoustic performance: mineral fiber and wool are natural sound absorbers that reduce noise and create a comfortable and productive environment.- Fire resistance: mineral fiber and wool are non-combustible and can withstand high temperatures, ensuring safety and compliance with building codes and regulations.- Moisture resistance: mineral fiber and wool can resist humidity, condensation, and sagging, preventing mold, mildew, and deterioration.- Thermal insulation: mineral fiber and wool can conserve energy and reduce heating and cooling costs by providing effective insulation against heat transfer.- Aesthetics: TNT Quality Mineral Fiber Ceilings and Boards' products come in a variety of colors, patterns, textures, and sizes, allowing for creative and customized design options that enhance the visual appeal and functionality of any space.- Sustainability: mineral fiber and wool are eco-friendly, recyclable, and contribute to LEED certification points.TNT Quality Mineral Fiber Ceilings and Boards' commitment to customer satisfaction is evident in its personalized service, fast delivery, competitive pricing, and responsive technical support. They work closely with their clients to understand their needs, provide recommendations, and offer solutions that meet their specific requirements and budget.The company's success is also due to its emphasis on innovation and adaptation to market changes. They continuously invest in research and development to improve their products' performance, quality, and durability. They also keep abreast of emerging trends and technologies, such as digital printing, LED lighting, and acoustic testing, to offer the latest and most advanced ceiling solutions.In conclusion, TNT Quality Mineral Fiber Ceilings and Boards' products have proven themselves to be reliable, versatile, and attractive solutions for all types of commercial construction projects. Their commitment to quality, sustainability, innovation, and customer service sets them apart from their competitors and positions them to meet the growing demand for high-performance ceilings that enhance the built environment and the well-being of its occupants.

Affordable Gypsum Ceiling Pressing Machine Emerges as a Game-changer

Cheap Gypsum Ceiling Pressing Machine Revolutionizes the Construction IndustryIn an era where technological advancements are transforming every sector, the construction industry is no exception. Gone are the days when workers had to rely solely on manual labor, as innovative machinery now takes center stage. The introduction of the Cheap Gypsum Ceiling Pressing Machine by an esteemed company marks a significant leap forward in construction technology. With its efficient design, superior performance, and affordable price, this cutting-edge machine is revolutionizing gypsum ceiling installation techniques.The Cheap Gypsum Ceiling Pressing Machine, developed by a forward-thinking industry leader, has quickly gained traction due to its outstanding features and unrivaled capabilities. By incorporating state-of-the-art technology, this machine provides a seamless and efficient solution to the tedious process of gypsum ceiling installation. The company, known for its expertise in engineering solutions, has designed this machine to cater to the needs of construction professionals in a cost-effective manner.One of the most notable advantages of the Cheap Gypsum Ceiling Pressing Machine is its easy operation. With user-friendly controls, even workers with limited experience can operate the machine without complications. This allows construction companies to save both time and money by reducing the training required for their workforce. The machine's intuitive interface ensures that it can be operated efficiently, leading to increased productivity.Furthermore, this groundbreaking machine boasts exceptional performance capabilities, surpassing those of its competitors. The innovative design allows the Cheap Gypsum Ceiling Pressing Machine to press gypsum boards quickly and accurately onto the ceiling framework, resulting in seamless installations. The machine's precision guarantees a smooth finish, eliminating the need for further touch-ups, and ensuring customer satisfaction.The affordability of the Cheap Gypsum Ceiling Pressing Machine is another key factor that sets it apart from other machines in the market. With its competitive price range, this machine offers construction companies an opportunity to enhance their productivity without breaking the bank. The lower initial investment required for this machine makes it an attractive option, particularly for small and medium-sized enterprises looking to expand their capabilities.The company behind the Cheap Gypsum Ceiling Pressing Machine has a rich history of engineering excellence. With years of experience in the construction industry, they have fine-tuned their machinery to meet the evolving needs of professionals in the field. Recognized for their commitment to quality and customer satisfaction, the company ensures that their products are built to withstand the rigorous demands of the construction sector.In addition to the Cheap Gypsum Ceiling Pressing Machine, the company offers a wide range of other construction machinery and equipment. From versatile tools to cutting-edge technology, their product catalog caters to various construction needs. With a well-established global presence and a network of trusted distributors, the company has positioned itself as a go-to source for reliable and high-performing machinery.As the construction industry progresses towards automation and efficiency, the Cheap Gypsum Ceiling Pressing Machine emerges as a game-changer. Its groundbreaking features, user-friendly operation, exceptional performance, and affordable price make it an invaluable asset to construction professionals worldwide. This technological advancement not only simplifies the installation process but also elevates the overall quality of gypsum ceiling projects.In conclusion, the introduction of the Cheap Gypsum Ceiling Pressing Machine by a renowned company brings a new era of innovation to the construction industry. With its remarkable features, this machine surpasses its competitors in terms of performance, ease of use, and affordability. As construction professionals continue to seek efficient and cost-effective solutions, the Cheap Gypsum Ceiling Pressing Machine stands out as an invaluable addition to their arsenal of tools.

Affordable Mineral Fiber Sheet Board Machine: A Budget-Friendly Option for Manufacturing

The demand for efficient and environmentally-friendly construction materials has been growing around the world. To meet this demand, companies have been developing new and innovative products that offer cost-effective solutions to the construction industry. One such company that has been leading the industry with its cutting-edge products is a high-end machinery manufacturer.The company has been producing quality products for over 20 years, with a focus on research and development of mineral fiber sheet board machinery. The company’s success can be attributed to its innovations in manufacturing, providing clients with cost-effective, efficient equipment that meets the highest standards of safety, quality, and reliability.Recently, the company announced the launch of its new Cheap Mineral Fiber Sheet Board Machine. The product is a breakthrough in technology and efficiency. The device has been specially designed to simplify and streamline the process of manufacturing mineral fiber sheet board.The machine, based on the company's proprietary technology, is designed to automate the process, making it faster, safer, and more environmentally-friendly. The new device offers a significant improvement in the production of mineral fiber sheet board, ensuring smoother and faster completion of construction projects.The machine features a highly efficient production line that can produce boards of varying thickness and width. The machine utilizes mineral wool, glass wool, and other environmentally-friendly materials to produce high-quality sheets that weigh about 0.1 to 0.2 g/ml.The new machine uses a variety of advanced technologies to enhance the safety and durability of the board. For instance, it has a unique feeding system that allows for the uniform distribution of mineral wool and glass wool over the width of the board. It also has a durable cutting mechanism that ensures clean and precise cuts.The device has a high degree of automation, making the manufacturing process faster and more efficient. It also has a user-friendly interface that simplifies operation and reduces the need for specialized knowledge or expertise.According to a company spokesperson, the Cheap Mineral Fiber Sheet Board Machine has been designed to help contractors reduce their production costs while providing high-quality and environmentally-friendly materials for their construction projects. The machine can make a significant contribution to the construction industry by reducing the time and cost of construction while maintaining the highest standards of quality and safety.The device has been developed with considerable emphasis on energy savings, reducing greenhouse gas emissions, and minimizing the use of fossil fuels. It also offers low-water usage, significantly reducing water consumption during the manufacturing process.The new machine is expected to have a significant impact on the global construction industry, with many contractors already expressing interest in purchasing the machine. The product's launch has been welcomed by many contractors and construction companies who have been looking for ways to produce environmentally-friendly construction materials.The new Cheap Mineral Fiber Sheet Board Machine is a testament to the company’s commitment to research and development and its desire to provide the highest quality of service to its clients. This innovation promises to revolutionize the construction industry, bringing significant benefits to contractors and construction companies interested in producing high-quality and cost-effective environmentally-friendly construction materials.In conclusion, the announcement of the new Cheap Mineral Fiber Sheet Board Machine is an important milestone for the construction industry. The device’s high degree of automation, user-friendly interface, and focus on energy savings and environmental sustainability make it unique in the market. Its launch promises to make a significant contribution to the industry by providing an efficient, cost-effective, and environmentally-friendly solution for the construction of buildings. The machine’s success is a testament to the company's commitment to innovation and its dedication to providing its clients with the best products and services possible.

Effective Slurry Distribution for Multiple Screens: PU Dewatering Screen with Vibrating Motor

As the demand for high-quality mineral fiber ceiling board increases, so does the need for efficient and reliable production equipment. Fortunately, there are now several top-grade Mineral Fiber Ceiling Board Machine factories that offer state-of-the-art production machinery and systems designed to meet the demands of modern manufacturing.One of the best ways to achieve high-quality ceiling boards is by using mineral fiber materials, which are known for their sound absorption, fire resistance, and thermal insulation properties. These materials are derived from naturally occurring minerals, such as basalt, perlite, and volcanic rock, which are then processed and combined with various binders, such as starch or resin.To produce mineral fiber ceiling boards, a Mineral Fiber Ceiling Board Machine is used to mix and form the materials into panels or tiles of varying sizes and densities. These machines utilize advanced technologies, such as heating and pressing, to create a strong and durable product that meets the required specifications.When selecting a Mineral Fiber Ceiling Board Machine factory, it is essential to consider some critical factors that will ensure optimal performance, reliability, and cost-effectiveness. Some of these factors include:Quality of the MachinesA high-quality Mineral Fiber Ceiling Board Machine should be durable, reliable, and easy to operate. The quality of the materials used in the manufacturing process is also critical, as low-quality materials can lead to frequent breakdowns and maintenance issues.Production CapacityThe production capacity of the Mineral Fiber Ceiling Board Machine should meet the needs of your manufacturing facility. It is essential to choose a machine that can handle your desired output without compromising on quality or efficiency.Maintenance and SupportChoosing a reputable Mineral Fiber Ceiling Board Machine factory that offers reliable maintenance and technical support ensures minimal downtime and maximum productivity. It is essential to choose a factory that provides regular maintenance and repair services and offers quick response times in case of any technical issues.Cost-effectivenessThe cost of the equipment and its maintenance should be within your budget. Choosing a Mineral Fiber Ceiling Board Machine factory that offers affordable solutions without compromising on quality or efficiency is critical to the success of your manufacturing plant.ConclusionMineral fiber ceiling board production has come a long way in recent years, thanks to advanced Mineral Fiber Ceiling Board Machine technology. By selecting a quality Mineral Fiber Ceiling Board Machine factory, you can ensure that your manufacturing plant produces high-quality, cost-effective, and efficient mineral fiber ceiling boards. Contact a reputable factory today to get the best mineral fiber ceiling board production machinery for your facility.