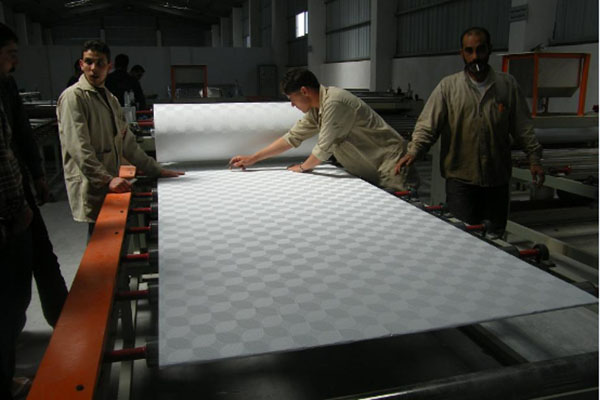

Affordable Mineral Fiber Sheet Equipment Manufacturing Plants

By:Admin

One such prominent factory is located in {}, which has established itself as a leader in the production of mineral fiber sheet equipment. With a focus on innovation and high-quality standards, the factory has become a preferred choice for many companies in need of reliable and affordable mineral fiber sheet equipment.

The company's state-of-the-art manufacturing facility is equipped with advanced machinery and a team of skilled technicians who are dedicated to producing top-notch mineral fiber sheet equipment. The factory's commitment to quality and efficiency has earned it a strong reputation in the industry, making it a trusted partner for businesses looking to invest in mineral fiber sheet production.

In addition to its manufacturing capabilities, the factory also places a strong emphasis on research and development. By staying abreast of the latest technological advancements and industry trends, the company continually enhances its equipment to meet the evolving needs of its clients. This commitment to innovation has allowed the factory to stay ahead of the competition and maintain its position as a leading producer of mineral fiber sheet equipment.

Furthermore, the factory is known for its exceptional customer service. The company's team of experts is always available to provide guidance and support to clients, ensuring a seamless experience from the initial inquiry to the delivery of the equipment. This dedication to customer satisfaction has cultivated strong relationships with clients, many of whom continue to return to the factory for their mineral fiber sheet equipment needs.

The affordability of the mineral fiber sheet equipment produced by the factory is another key factor in its success. Despite its high-quality standards and advanced technology, the factory is able to offer its equipment at competitive prices, making it an attractive option for businesses of all sizes. This cost-effective approach has made the factory a preferred choice for companies looking to invest in mineral fiber sheet production without compromising on quality.

Looking ahead, the factory is poised for continued growth and expansion. With the increasing demand for mineral fiber sheet equipment, the company is focused on increasing its production capacity and further enhancing its technological capabilities. By staying at the forefront of industry trends and consistently delivering exceptional products and services, the factory is well-positioned to meet the evolving needs of its clients and maintain its status as a leader in the market.

In summary, cheap mineral fiber sheet equipment factories, such as the one located in {}, are playing a pivotal role in the manufacturing industry. With their dedication to quality, innovation, and affordability, these factories are meeting the growing demand for mineral fiber sheet equipment and providing businesses with reliable, cost-effective solutions. As the industry continues to evolve, these factories are set to remain at the forefront, driving innovation and delivering value to their clients.

Company News & Blog

Top Gypsum Board Cornice Automatic Equipment Manufacturers

[Company Name] has become a leading manufacturer of gypsum board cornice automatic equipment, establishing itself as one of the top factories in the industry. With a state-of-the-art production facility and a strong commitment to innovation, the company has been able to consistently deliver high-quality equipment that meets the needs of their customers.The factory, located in [Location], is equipped with cutting-edge technology and advanced machinery, allowing [Company Name] to produce a wide range of gypsum board cornice automatic equipment. This includes everything from cutting and shaping machines to automatic installation and finishing equipment. The company's production process is highly efficient, ensuring that they are able to meet the growing demand for their products while maintaining the highest standards of quality.One of the key factors that sets [Company Name] apart from other factories is their dedication to research and development. The company has a team of experienced engineers and designers who are constantly working to improve their equipment and develop new technologies. This has allowed [Company Name] to stay ahead of the curve in the industry, introducing innovative products that are not only more efficient, but also more environmentally friendly.In addition to their focus on technology and innovation, [Company Name] is also committed to sustainability and responsible manufacturing practices. The factory is designed to minimize waste and energy consumption, and the company is constantly looking for ways to reduce their environmental impact. This commitment to sustainability has earned [Company Name] recognition as a leader in the industry, and has helped them build a strong reputation among their customers and partners.Despite their success, [Company Name] remains focused on providing excellent customer service and support. The company works closely with their clients to understand their specific needs and requirements, and they are able to provide customized solutions that meet these needs. This level of support has helped [Company Name] build long-lasting relationships with their customers, and has contributed to their strong reputation in the industry.Looking to the future, [Company Name] is committed to continuing their growth and development. The company is constantly looking for new opportunities to expand their product line and reach new markets. They are also committed to staying at the forefront of technological advancements, ensuring that they are able to provide their customers with the most innovative and efficient equipment on the market.In conclusion, [Company Name] has established itself as one of the top factories in the industry for gypsum board cornice automatic equipment. With a focus on technology, innovation, and sustainability, the company has been able to deliver high-quality products that meet the needs of their customers. Their commitment to customer service and support has helped them build strong relationships with their clients, and their dedication to growth and development ensures that they will continue to be a leader in the industry for years to come.

Plastic Extruder Production Line: Energy Efficient and Cost-Effective

When it comes to manufacturing XPS insulation boards, the technology and equipment used in the production process are crucial aspects that can determine the quality and efficiency of the end product. One of the most critical pieces of equipment in this process is the extruder, which plays a fundamental role in the production of XPS insulation boards.An extruder is a machine that transforms raw plastic materials into a consistent and uniform plastic profile that can be used in the production of various forms of plastic products. In the context of XPS insulation boards, the extruder plays a crucial role in melting and mixing polystyrene beads, allowing them to expand and grow into the rigid foam board structure used in insulation applications.If you're looking for a reliable and energy-efficient extruder for your XPS production line, then you should consider the options available from Chinese manufacturers. China Plastic Extruder manufacturers have been making significant strides in recent years, with innovations aimed at improving the efficiency and performance of their equipment.One of the key features of the extruders manufactured by China Plastic Extruder manufacturers is energy efficiency. The use of advanced technology to improve energy efficiency can result in significant cost savings for the manufacturer in the long run. This feature has become increasingly crucial in recent years, as more companies begin to implement sustainable manufacturing practices.Another key feature of the extruders from Chinese manufacturers is stability and efficiency with high capacity. This feature ensures that the extruders can handle high volumes of materials without compromising the quality of the output. This aspect is particularly important in an industry where efficiency and consistency are so crucial.Additionally, Chinese extruders can support the use of CO2, butane, and LPG as foam agents without CFC, HFC, HCFC. This feature makes them an environmentally friendly option for manufacturers looking to minimize their carbon footprint. Furthermore, the extruders are compatible with HFC and HCFC as foam agents, providing greater flexibility in the production process.Finally, the extruders from Chinese manufacturers are compatible with recycled materials to reduce costs. This feature is essential in today's circular economy, where there is an increasing demand for eco-friendly and sustainable manufacturing practices. As such, these extruders are perfectly positioned to meet the needs of XPS insulation board manufacturers looking to reduce their environmental impact.In conclusion, the extruder is a crucial component in the XPS insulation board production process. The latest models from China Plastic Extruder manufacturers come equipped with advanced features that are designed to improve efficiency, reduce costs, and promote sustainable manufacturing practices. If you're looking for an extruder for your XPS production line, then you should definitely check out what Chinese manufacturers have to offer.

Affordable Mgo Board Making Machine: A Complete Pricelist

Today, we are excited to introduce a new Mgo Board Making Machine that is set to revolutionize the construction industry. The Mgo Board Making Machine is a versatile and efficient piece of equipment that is designed to produce high-quality magnesium oxide boards for various construction applications. The machine is engineered to provide superior performance, speed, and precision, making it an essential addition to any construction operation.The Mgo Board Making Machine offers a wide range of benefits that make it a valuable asset for any construction business. The machine is capable of producing Mgo boards of various sizes and thicknesses, allowing for versatility in construction projects. Additionally, the machine is equipped with advanced technology that ensures uniform board density and smooth surface finish, resulting in superior quality boards that meet industry standards.In terms of efficiency, the Mgo Board Making Machine is designed to optimize production processes, minimize material waste, and reduce labor costs. The machine features a user-friendly interface and automated controls that enable easy operation and monitoring of the production process. This enables construction companies to increase their productivity and meet project deadlines with ease.Furthermore, the Mgo Board Making Machine is built to be durable and reliable, ensuring long-term performance and minimal maintenance requirements. The machine is constructed with high-quality materials and components, and it undergoes stringent quality testing to guarantee its reliability and longevity. This means that construction businesses can rely on the Mgo Board Making Machine to deliver consistent results and minimize downtime.The introduction of the Mgo Board Making Machine is a significant milestone for our company. We are dedicated to providing innovative solutions that empower construction businesses to thrive in today's competitive market. The Mgo Board Making Machine reflects our commitment to delivering high-performance equipment that meets the evolving needs of the construction industry.As a leading manufacturer (), we have a strong track record in developing cutting-edge machinery that enhances construction processes. Our team of experienced engineers and technicians has worked tirelessly to design and create the Mgo Board Making Machine, ensuring that it meets the highest standards of quality, performance, and reliability. We are confident that the machine will make a positive impact on construction operations and contribute to the success of our customers.In conclusion, the Mgo Board Making Machine is a game-changer for the construction industry. Its advanced technology, efficiency, and reliability make it an essential investment for construction businesses looking to enhance their production capabilities and deliver high-quality results. With the introduction of this innovative machine, we are proud to continue our legacy of excellence in providing industry-leading solutions for the construction sector.For more information about the Mgo Board Making Machine and its pricing, please contact us at () or visit our website at (). We look forward to assisting you in integrating this groundbreaking machine into your construction operations and helping you achieve your business goals.

Affordable Mineral Fiber False Ceiling Tiles Machine Pricelist

In today's fast-paced world, businesses and industries are constantly looking for cost-effective and efficient solutions to meet their needs. This is where the innovative technology of mineral fiber false ceiling tiles machines comes into play. These machines are designed to produce high-quality false ceiling tiles at a fraction of the cost compared to traditional methods. With their competitive price list, these machines are making waves in the market and are becoming a popular choice for businesses looking to streamline their production process.The mineral fiber false ceiling tiles machine is the brainchild of a leading manufacturing company in the industry. With years of experience and a commitment to innovation, this company has developed a range of cutting-edge machines that are revolutionizing the way false ceiling tiles are produced. Their machines are designed to be user-friendly, efficient, and cost-effective, making them an ideal choice for businesses of all sizes.One of the key advantages of these machines is their ability to produce high-quality false ceiling tiles at a significantly lower cost. This is achieved through a combination of advanced technology and smart manufacturing processes. The machines are capable of producing a wide range of false ceiling tiles with different designs, dimensions, and specifications, allowing businesses to meet their unique requirements with ease.Furthermore, these machines are designed to be highly efficient, allowing businesses to increase their production capacity and meet growing demand without incurring significant costs. This is particularly beneficial for businesses operating in competitive markets where cost-effective production is crucial for success.The company behind these machines is committed to providing top-notch customer service and support to ensure that businesses can maximize the potential of their investment. They offer comprehensive training and technical support, ensuring that businesses can seamlessly integrate these machines into their production processes and start reaping the benefits right away.In addition to their competitive price list, the company also offers flexible financing options to make their machines accessible to businesses of all sizes. This is a testament to their commitment to supporting businesses and helping them thrive in today's highly competitive market.The mineral fiber false ceiling tiles machine has already garnered attention from businesses across various industries. From construction companies to interior design firms, businesses are recognizing the value of these machines in streamlining their production processes and reducing their operational costs. With their cost-effective and efficient performance, these machines are poised to become a game-changer in the false ceiling tiles manufacturing industry.In conclusion, the mineral fiber false ceiling tiles machine from [company name] is setting a new standard in cost-effective and efficient production. With their competitive price list, advanced technology, and unwavering commitment to customer support, this company is empowering businesses to take their production capacity to the next level. As the demand for high-quality false ceiling tiles continues to grow, these machines are proving to be a valuable asset for businesses looking to stay ahead of the curve.

Professional Plastering Services for New Builds, Repairs, and Renovations

Brad McKinnon Plastering: The Leading Plastering Service ProviderLooking to renovate your home or building a new house from scratch? Then, Brad McKinnon Plastering has got you covered! Providing top-notch plastering services, Brad McKinnon Plastering is the leading company in New Zealand, known for delivering quality and timely services to clients.At Brad McKinnon Plastering, we understand the vital role that plastering plays in the construction industry, and our dedicated team of experts takes great pride in providing top-quality services that exceed our clients' expectations. Our commitment to quality and excellence has made us one of the most preferred plastering providers in the industry.New Build ServicesBuilding a house from scratch is a significant investment in one's life, and we understand that. Hence, we offer New Build services like no other. Our team of experts is knowledgeable, reliable and equipped with the latest technology and tools to ensure that your new build is perfect. We pay attention to every detail, from layout to design, and from plastering to painting. We ensure that our clients' vision comes to fruition, and their dream home is realized.Repair ServicesAt some point, even the most robust of buildings require repairs. Whether it's a small crack or significant damage, fret no more, as Brad McKinnon Plastering offers reliable repair services to maintain the aesthetics and integrity of your walls and ceilings. Our team of experts is equipped with the necessary skills and tools to tackle any repair job, no matter how big or small the issue may seem.Renovation ServicesThinking of a home makeover? Brad McKinnon Plastering is here to help. Our renovation services are bespoke and tailored to suit our clients' needs. We understand that every client has unique taste, and we take pride in listening and working with our clients to achieve their desired results. We employ the latest techniques to ensure that the result is not only visually appealing but exceeds our clients' expectations.Full Skim Level 5 ServicesIf you require the most polished finish, then our Full Skim Level 5 services are perfect for you. Our experts use the latest technology and tools to provide beautiful, level five finishes that will leave your walls and ceiling with the most beautiful, polished finish. Our team is dedicated to delivering exceptional work and will ensure that every detail is perfect.GIB CoveBrad McKinnon Plastering offers GIB Cove services, one of the most distinguishing features of any room. Our expert team ensures that the GIB Cove in your room is bespoke and tailored to your requirements and style. With our GIB Cove services, you can rest assured that your room will be transformed into a beautiful space.Plaster CorniceOne of the most essential aspects of plastering is Plaster Cornice. It enhances the aesthetics of any room and provides that extra finishing touch that can make all the difference. At Brad McKinnon Plastering, we specialize in Plaster Cornice and offer bespoke services that will transform your room.ConclusionBrad McKinnon Plastering is the most trusted and reliable plastering service provider in New Zealand. Our team of dedicated experts is equipped with the latest technology and tools to ensure that every job is perfect. We pay great attention to detail and are committed to delivering quality and timely services that exceed our clients' expectations. Contact us today, and let's help you transform your home.

Affordable Automatic Gypsum Cornice Making Machine Manufacturers

Cheap Automatic Gypsum Cornice Making Machine Factories are becoming increasingly popular in the manufacturing industry. These factories are revolutionizing the way gypsum cornice products are produced, making it more efficient and cost-effective for companies to meet their production needs. One such company that is leading the charge in this industry is {}.{} is a renowned company that specializes in the manufacturing of automatic gypsum cornice making machines. With their state-of-the-art technology and innovative approach to production, they have quickly become a top choice for businesses looking to invest in high-quality and affordable machinery.One of the key factors that set {} apart from other competitors in the industry is their commitment to providing cheap, automatic gypsum cornice making machines that are of the highest quality. By utilizing advanced manufacturing techniques and cutting-edge technology, {} is able to produce top-of-the-line machinery at a fraction of the cost of their competitors.In addition to their focus on affordability, {} is also committed to providing excellent customer service and support. They understand that investing in machinery is a significant decision for any business, and they strive to ensure that their clients have all the information and assistance they need to make the best choices for their production needs.With a team of highly skilled and experienced professionals, {} is able to offer comprehensive support to their clients at every stage of the process. From initial consultations to installation and ongoing maintenance, {} is dedicated to providing a seamless and stress-free experience for their customers.The automatic gypsum cornice making machines produced by {} are designed to maximize efficiency and productivity. These machines are capable of producing a wide range of gypsum cornice products with precision and consistency, making them an ideal solution for businesses looking to streamline their production processes.Furthermore, {} is constantly innovating and improving their machinery to stay ahead of the curve in the industry. They are always exploring new technologies and methodologies to enhance the performance and capabilities of their machines, ensuring that their clients have access to the most advanced and reliable equipment on the market.In addition to their commitment to quality and innovation, {} also prioritizes sustainability and environmental responsibility in their manufacturing processes. They are dedicated to minimizing waste and reducing their carbon footprint, making them a responsible and conscientious choice for businesses that are mindful of their impact on the environment.As a leading manufacturer of cheap automatic gypsum cornice making machines, {} is well-positioned to meet the growing demand for efficient and cost-effective production solutions in the industry. With their unwavering dedication to quality, affordability, and customer satisfaction, {} is poised to continue making a positive impact on businesses looking to optimize their production processes.In conclusion, the rise of cheap automatic gypsum cornice making machine factories is reshaping the manufacturing landscape, and companies like {} are at the forefront of this revolution. By offering high-quality, affordable machinery and exceptional customer support, {} is helping businesses around the world achieve their production goals with ease and efficiency. As the industry continues to evolve, {} will undoubtedly remain a key player in driving this positive change.

High-Quality Gypsum Cornice Production Line for Efficient Manufacturing

Best Gypsum Cornice Production Line Revolutionizes Manufacturing ProcessIn the ever-evolving world of manufacturing, one company has set the bar high with their innovative gypsum cornice production line. With a commitment to quality and efficiency, they have quickly become a leader in the industry.With a strong focus on research and development, {Company Name} has successfully created the best gypsum cornice production line in the market. This state-of-the-art line has revolutionized the manufacturing process, increasing productivity, and ensuring top-quality products every time.{Company Name} was founded in 1995, and since its inception, has been dedicated to providing the best solutions for the construction industry. With a team of highly skilled engineers and technicians, the company has been able to develop cutting-edge technology that has set them apart from their competitors.Their gypsum cornice production line is a result of years of research and development, with a relentless pursuit of perfection. The line is equipped with the latest technology, allowing for precise and efficient production of gypsum cornices. This has significantly reduced production time and increased output, ultimately leading to cost savings for the company.The production line is also designed to ensure the highest quality of products. With automated processes and rigorous quality control measures in place, {Company Name} guarantees that every gypsum cornice that comes off the line meets the highest standards. This has earned them a reputation for excellence in the industry and has solidified their position as a top choice for customers.One of the key features of the {Company Name}'s gypsum cornice production line is its versatility. The line is capable of producing a wide range of gypsum cornices in various sizes and designs, allowing the company to cater to the diverse needs of their customers. Whether it's a simple and elegant design or a more intricate and ornate one, the production line can handle it all with ease.Furthermore, the production line is also designed with sustainability in mind. {Company Name} is committed to reducing its environmental impact, and the production line is equipped with energy-efficient technology that helps minimize resource consumption. This has not only been beneficial for the environment but has also reduced operational costs for the company.Moreover, {Company Name} provides comprehensive training and support to its customers to ensure that they can fully maximize the potential of the production line. Their team of professionals is dedicated to providing assistance and guidance, helping their customers achieve the best results with the equipment.The {Company Name}'s gypsum cornice production line has received widespread acclaim from customers and industry professionals alike. Its impact on the manufacturing process has been significant, with many customers reporting increased efficiency and cost savings since implementing the production line in their facilities.With their commitment to innovation and excellence, {Company Name} continues to push the boundaries of what is possible in manufacturing. Their gypsum cornice production line is a testament to their dedication to providing the best solutions for the construction industry, and it has set a new standard for efficiency and quality.

High-Quality Foam Extrusion Line for XPS Production

XPS Foam Extrusion Line Improves Production EfficiencyThe demand for high-quality insulation materials has been steadily increasing in recent years, driven by the construction industry's focus on energy efficiency and sustainable building practices. In response to this growing demand, [Company Name] has unveiled its latest XPS Foam Extrusion Line, which promises to revolutionize the production of extruded polystyrene (XPS) foam insulation.The new XPS Foam Extrusion Line represents a significant leap forward in technology, offering improved production efficiency, higher output capacity, and enhanced product quality. By incorporating the latest advancements in extrusion technology, [Company Name] has solidified its position as a leader in the manufacturing of XPS foam insulation.One of the key features of the new extrusion line is its increased production efficiency. The line is equipped with state-of-the-art machinery and automation systems, allowing for higher production speeds and reduced downtime. This means that [Company Name] can now meet the growing demand for XPS foam insulation more efficiently, without compromising on quality.In addition to improving production efficiency, the new extrusion line also boasts a higher output capacity. This means that [Company Name] can produce larger quantities of XPS foam insulation in a shorter amount of time, allowing the company to better serve its customers and fulfill large orders more quickly.Furthermore, the new extrusion line has been designed to enhance product quality. By utilizing advanced manufacturing processes and quality control measures, [Company Name] can ensure that its XPS foam insulation meets the highest standards for performance and durability. This is crucial for customers who rely on XPS foam insulation to provide long-lasting and effective thermal insulation in their buildings.In addition to the technical advancements of the new extrusion line, [Company Name] has also made significant investments in research and development to further improve the performance and sustainability of its XPS foam insulation. By leveraging its expertise in materials science and engineering, [Company Name] has developed innovative formulations and production techniques that enhance the thermal efficiency and environmental sustainability of its XPS foam insulation products.In light of these advancements, [Company Name] is confident that its new XPS Foam Extrusion Line will reinforce its position as a preferred supplier of XPS foam insulation in the construction industry. With its commitment to innovation, quality, and sustainability, [Company Name] is poised to meet the evolving needs of its customers and contribute to the ongoing advancement of energy-efficient and sustainable building practices.[Company Name] is a leading manufacturer of XPS foam insulation, offering a comprehensive range of solutions for residential, commercial, and industrial applications. With a focus on innovation, quality, and sustainability, [Company Name] is dedicated to providing high-performance insulation materials that contribute to energy efficiency and environmental responsibility.As a responsible corporate citizen, [Company Name] is committed to sustainable manufacturing practices and environmental stewardship. The company's XPS foam insulation products are designed to minimize environmental impact and contribute to green building initiatives, making them a preferred choice for architects, contractors, and building owners who prioritize sustainability.Overall, the introduction of the new XPS Foam Extrusion Line marks a significant milestone for [Company Name], as it underscores the company's dedication to excellence and innovation in the field of insulation materials. With its superior production efficiency, increased output capacity, and enhanced product quality, the new extrusion line is poised to elevate [Company Name]'s position in the market and meet the growing demand for high-quality XPS foam insulation.

Top Affordable Gypsum Decorative Tile Making Machine Pricelist

.Gypsum decorative tiles are gaining popularity in the construction industry due to their versatility and aesthetic appeal. These tiles are widely used for interior decoration in homes, offices, and other commercial spaces. As the demand for gypsum decorative tiles continues to rise, the need for advanced manufacturing equipment is also growing.In response to this demand, {Company Name} has announced the launch of their latest gypsum decorative tile making machine. This state-of-the-art machine is designed to produce high-quality gypsum tiles with precision and efficiency, catering to the needs of the modern construction industry.The {Company Name} gypsum decorative tile making machine is equipped with advanced technology and features that set it apart from traditional tile making machines. It has a high-speed production capability, allowing for increased output and faster turnaround times. The machine also boasts a user-friendly interface, making it easy for operators to control and monitor the production process.One of the key highlights of this machine is its ability to create a wide variety of tile designs. Whether it's intricate patterns, textured surfaces, or customized shapes, the {Company Name} gypsum decorative tile making machine is capable of producing diverse tile designs to meet the specific requirements of their customers. This flexibility makes it an ideal choice for manufacturers looking to offer unique and innovative gypsum decorative tiles in the market.In addition to its advanced features, the {Company Name} gypsum decorative tile making machine is also designed for durability and low maintenance. This ensures that manufacturers can rely on the machine for long-term production without compromising on quality or efficiency. The machine is also equipped with safety features to ensure the well-being of its operators, making it a reliable and secure investment for manufacturing facilities.Furthermore, {Company Name} prides itself on its commitment to providing top-notch customer service and support. As a leading manufacturer of gypsum decorative tile making machines, the company offers comprehensive training and technical assistance to help their customers maximize the potential of their equipment. This includes installation services, operational training, and ongoing maintenance support, ensuring that their clients can make the most out of their investment.With the launch of their latest gypsum decorative tile making machine, {Company Name} aims to cater to the growing needs of the construction industry for high-quality and innovative gypsum decorative tiles. The company's dedication to technological advancement and customer satisfaction underscores their position as a leader in the manufacturing equipment market.The {Company Name} gypsum decorative tile making machine has already garnered attention from industry professionals and manufacturers, who recognize its potential to revolutionize the production of gypsum decorative tiles. With its advanced capabilities, user-friendly interface, and robust design, the machine is poised to set a new standard for manufacturing efficiency and quality in the industry.As the construction industry continues to embrace gypsum decorative tiles as a preferred choice for interior decoration, the demand for advanced manufacturing equipment will only increase. With the introduction of the {Company Name} gypsum decorative tile making machine, manufacturers now have access to a cutting-edge solution that can meet their production needs and exceed the expectations of their customers.In conclusion, the launch of the {Company Name} gypsum decorative tile making machine represents a significant milestone for the construction industry. With its innovative features, flexibility, and reliability, the machine is set to redefine the manufacturing process for gypsum decorative tiles, offering manufacturers the opportunity to create stunning and unique tiles for various applications. As {Company Name} continues to lead the way in providing advanced manufacturing solutions, the future of gypsum decorative tile production looks brighter than ever.

Top Manufacturers of Magnesium Plate Board Machines Revealed in Latest News

[News Title]: A Breakthrough in Magnesium Plate Board Production: Innovative Machine Introduced by Leading Manufacturers[News Content]:[date]Magnesium has long been recognized as a versatile metal with numerous industrial applications. Its lightweight, high strength, and exceptional resistance to corrosion have made it a popular choice for manufacturers across various sectors. Considered a superior alternative to traditional materials such as aluminum, steel, and plastic, magnesium plates have become increasingly sought after in recent years for use in construction, automotive, aerospace, and other industries. In line with the growing demand, {Company Name}, a leading manufacturer in the field, has introduced an innovative magnesium plate board machine that promises to revolutionize the production process.{Company Name}, operating for over [number of years] years, has established itself as a trusted name in the industry. Driven by a commitment to innovation, the company has continuously invested in research and development to improve the efficiency and quality of their products. The introduction of their new magnesium plate board machine represents a significant milestone for both the company and the industry as a whole.The cutting-edge machine, developed by a team of skilled engineers and technicians, combines state-of-the-art technology with years of experience in magnesium processing. The unique design of the machine allows for precise control over the production process, resulting in magnesium plates of unparalleled quality. With the ability to produce a wide range of thicknesses and sizes, the machine caters to the diverse needs of customers in various sectors.One of the key features of the new machine is its enhanced automation capabilities. Through an advanced control system, the machine can streamline production, ensuring a faster and more efficient manufacturing process. This not only maximizes output but also reduces human error, leading to consistently high-quality magnesium plates. Furthermore, the machine's automated material feeding system optimizes resource utilization, minimizing waste and improving overall sustainability.In addition to its exceptional performance, the magnesium plate board machine developed by {Company Name} prioritizes worker safety. Equipped with multiple safety features, including emergency stop buttons and protective barriers, the machine ensures a safe operating environment for its operators. This focus on occupational health and safety reflects the company's dedication to promoting a responsible and sustainable manufacturing process.{Company Name}'s commitment to quality extends beyond the machine itself. As a socially responsible manufacturer, the company sources its magnesium from certified suppliers, ensuring compliance with international standards and best practices. This not only guarantees the integrity of the final product but also contributes to a more sustainable supply chain overall.Given the ever-growing demand for magnesium plates, {Company Name}'s introduction of this advanced machine marks a significant step forward for the industry. By combining cutting-edge technology, efficient production processes, and a commitment to quality and safety, the company solidifies its position as a leader in the magnesium plate board manufacturing sector.Looking ahead, {Company Name} plans to continue its research and development efforts, aiming to further improve the machine's capabilities. Through ongoing innovation, they strive to meet evolving market demands, enhance customer satisfaction, and contribute to the advancement of the magnesium industry as a whole.In conclusion, the introduction of {Company Name}'s innovative magnesium plate board machine represents a groundbreaking development for the industry. With its advanced automation, emphasis on safety, and commitment to quality, the machine is set to reshape the production of magnesium plates, catering to the increasing demand across various sectors. As a leading manufacturer, {Company Name} continues to demonstrate its dedication to pushing boundaries and driving progress within the magnesium industry.