Lightweight Wall Panel Production Line for Mgo Board - Benefits and Cost Analysis

Jinan Zhongke Building Material Machinery Co., Ltd., a leading building material machinery manufacturer in China, has recently launched its latest Mgo Board Light Weight Wall Panel Production Line. The product line is designed to produce high-quality wall panels that are lightweight, fire-resistant, waterproof, and energy-efficient.The company has invested heavily in research and development to create a leading-edge Mgo Board Light Weight Wall Panel Production Line that is capable of producing wall panels of up to 3660mm*1220mm*3mm size at a rate of 1-30m/min. The production line is energy-efficient, cost-effective, and requires minimal labor for operation.According to the benefit analysis conducted by Jinan Zhongke Building Material Machinery Co., Ltd., the cost accounting for producing one wall panel includes raw material cost, water-electricity fee, and labor cost. The raw material cost for one panel is 15 yuan/piece, which is significantly lower than the price of traditional wall panels. The water-electricity fee is 0.2 yuan/piece, and the labor cost is 1.5 yuan/piece. Therefore, the total cost for one panel is 16.7 yuan/piece, which is much lower than the cost of traditional wall panels.Moreover, the Mgo Board Light Weight Wall Panel Production Line is fully automated, requiring only two workers for its operation. Thus, the labor cost is reduced, leading to higher profits for the manufacturers. The production line also has a low energy consumption rate, which reduces the overall manufacturing costs and is environmentally friendly.Jinan Zhongke Building Material Machinery Co., Ltd. is a reputable manufacturer that prioritizes customer satisfaction. The company has a team of experienced and professional engineers who provide customization services to meet the specific requirements of its clients.The Mgo Board Light Weight Wall Panel Production Line is suitable for manufacturing various types of lightweight wall panels, including partition walls, external walls, internal walls, and fire-resistant walls. The wall panels can be used in various residential and commercial buildings, such as hotels, schools, hospitals, and office complexes.In conclusion, Jinan Zhongke Building Material Machinery Co., Ltd.'s latest Mgo Board Light Weight Wall Panel Production Line is a revolutionary product that will transform the construction industry. It is cost-effective, energy-efficient, and produces high-quality wall panels that have numerous benefits over traditional wall panels. The product line's superior quality design, advanced technology, and customization services set it apart from its competitors, making it the go-to product for all lightweight wall panel needs.

Read More

Affordable Roof Panel Roll Forming Machine Manufacturers and Suppliers in China with Stock Availability

If you're searching for affordable, high-quality roof panel roll forming machines, look no further than Xinhonghua. As a leading manufacturer and supplier of roll forming machines in China, we offer a comprehensive range of machines specifically designed to meet the needs of roofing contractors and others working in the construction industry. With our cheap prices and extensive inventory of machines, you're sure to find the perfect roll forming machine for your application.Our roof panel roll forming machines are meticulously designed and crafted to ensure high-quality, precision performance. We use only the best materials and components, and our machines are engineered to provide long-lasting, reliable service. Whether you're looking for a machine to produce metal roofing panels, corrugated panels, or other types of roofing panels, we have the perfect machine to meet your needs.In addition to roof panel roll forming machines, we also offer a range of other roll forming machines, including Cheap Mgo Board Forming Machine Pricelist. Our MGO board forming machines are designed to produce high-quality, fire-resistant MGO boards that are perfect for use in construction, interior finishing, and other applications. With our MGO board forming machines, you can easily produce high-volume quantities of boards quickly and efficiently.At Xinhonghua, we pride ourselves on our dedication to quality, reliability, and customer service. We understand that our success depends on the satisfaction of our customers, and we work tirelessly to ensure that our machines are up to the highest standards of excellence. Whether you're a small contractor or a large construction firm, we have the expertise and experience to provide you with the products and services you need to succeed.So if you're in the market for a new roof panel roll forming machine or Cheap Mgo Board Forming Machine Pricelist, be sure to contact us today. Our friendly and knowledgeable staff are always on hand to answer any questions you may have, and we're committed to providing you with the best possible service and support. Let us help you transform your construction business with high-quality, affordable rolling forming machines from Xinhonghua.

Read More

High-Quality Lightweight Wall Panel MGO Board Door Manufacturing Machinery for Magnesium Oxide Main Material

Read More

Foam Board Insulation Production Line Price List: Everything You Need to Know

The demand for energy-efficient and eco-friendly building materials has been on the rise in recent years, and one company is stepping up to meet this demand with their state-of-the-art XPS Foam Board Insulation Production Line.The production line, manufactured by the company, is designed to produce high-quality XPS foam board insulation, which is widely used in the construction industry for its excellent thermal insulation properties. The company has been a leading manufacturer of insulation solutions for the construction industry for many years, and their new production line is set to further solidify their position in the market.The XPS Foam Board Insulation Production Line is equipped with the latest technology, allowing for efficient and precise manufacturing of XPS foam boards. The production line is capable of producing a wide range of foam board thicknesses and densities to meet the specific needs of different construction projects. This versatility makes it an ideal choice for both residential and commercial applications.In addition to its advanced manufacturing capabilities, the production line also boasts high energy efficiency and low emissions, aligning with the company's commitment to sustainability. The use of XPS foam board insulation in construction projects can contribute to reducing energy consumption and greenhouse gas emissions, making it a popular choice for environmentally conscious builders and developers.Furthermore, the company offers a competitive pricing strategy for their XPS foam board insulation production line. By providing a pricelist that is reflective of the high quality and efficiency of the production line, they aim to make it accessible to a wide range of businesses within the construction industry. This affordability, combined with the superior performance of the insulation produced, positions the company as a go-to source for insulation solutions.With their XPS Foam Board Insulation Production Line, the company is poised to make a significant impact on the construction industry. By providing a reliable and efficient means of manufacturing XPS foam board insulation, they are empowering builders and developers to create more sustainable and energy-efficient buildings.The company's commitment to innovation and sustainability is further evident in their dedication to research and development. They continue to invest in improving their production processes and developing new and improved insulation solutions to meet the evolving needs of the construction industry.In conclusion, the introduction of the XPS Foam Board Insulation Production Line by the company represents a significant advancement in the field of construction insulation. With its cutting-edge technology, energy efficiency, and competitive pricing, it is set to revolutionize the way insulation materials are manufactured and used in building projects. As the demand for energy-efficient and environmentally friendly construction materials continues to grow, the company is well-positioned to lead the way with their innovative insulation solutions.

Read More

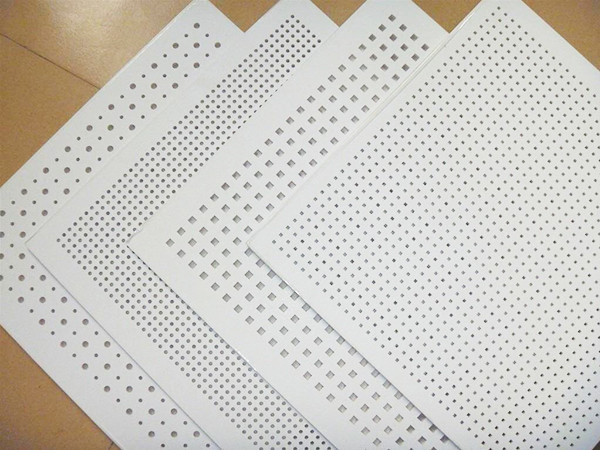

High-quality Magnesium Oxide Boards - Manufacturers and Suppliers in China

Magnesium Oxide Board: The Future of Building MaterialsThe construction industry has been using traditional building materials such as wood, concrete, and gypsum boards. However, these materials have their limitations in terms of strength, fire resistance, and moisture resistance, amongst others. This is where Magnesium Oxide boards come in, a material that is taking the construction industry by storm.Zhangjiagang Weiyu Art Glass Co., Ltd. is an established Magnesium Oxide board machine supplier that is committed to producing high-quality Magnesium Oxide boards with exceptional features that make them suitable for a wide range of construction applications.The Benefits of Magnesium Oxide BoardsMagnesium Oxide boards are made of magnesium oxide, which is a mineral compound that is naturally fire-resistant, mold-resistant, and moisture-resistant, making it an ideal material for interior and exterior applications. The boards are also environmentally friendly, non-toxic, and have excellent sound insulation capabilities.Here are some of the benefits of Magnesium Oxide boards:1. Fire-ResistantMagnesium Oxide boards are naturally fire-resistant, making them ideal for areas that require high fire safety standards. Magnesium oxide has a high melting point, making it non-combustible, which is a great feature to help minimize fire damage and ensure the safety of the building occupants.2. Strong and DurableThe strength of Magnesium Oxide boards is comparable to cement boards, but they are much more lightweight, making them easier to handle and install. The boards also have excellent dimensional stability, which means they won’t warp, rot, or decay over time as traditional building materials do.3. Water-ResistantMagnesium Oxide boards are moisture-resistant, and unlike gypsum boards, they don't absorb water, keeping them intact even in areas with high humidity. The boards also have excellent mold-resistance properties, keeping homes and buildings healthy and free from mold.4. Easy to Work WithMagnesium Oxide boards are easy to work with, and contractors can easily cut, shape, and drill them using regular tools. The boards are also screw and nail-friendly, making installation much faster and more straightforward.5. VersatileMagnesium Oxide boards come in a variety of sizes and thicknesses, making them perfect for various construction applications, including walls, ceilings, flooring, and roofing. They can also be coated with different finishes to achieve the desired aesthetic appeal.Why Choose Zhangjiagang Weiyu Art Glass Co., Ltd.?Zhangjiagang Weiyu Art Glass Co., Ltd. is a renowned Magnesium board machine supplier, and its Magnesium Oxide boards are made with the latest technology, ensuring consistency and quality in every board produced. The company has invested in advanced machinery that ensures efficient production, and its team has extensive knowledge and expertise in Magnesium Oxide board production.In addition to offering high-quality Magnesium Oxide boards, Zhangjiagang Weiyu Art Glass Co., Ltd. has a strong commitment to environmental conservation, and its products are eco-friendly, making them perfect for green construction.ConclusionMagnesium Oxide boards are revolutionizing the construction industry as they provide excellent strength, fire-resistance, and water-resistance properties, amongst many others. With Zhangjiagang Weiyu Art Glass Co., Ltd. as your Magnesium board machine supplier, you can be sure of high-quality Magnesium Oxide boards that are easy to work with and available in a variety of sizes and thicknesses. Contact us today for quality and reliable construction materials.

Read More

Highly Efficient Magnesium Oxide Board Making Machine

High Efficient Mgo Board Making Machine Revolutionizes Construction IndustryIn recent years, the construction industry has witnessed a rapid increase in the use of Magnesium Oxide (MgO) boards due to their numerous benefits such as fire resistance, moisture resistance, and durability. To meet the growing demand for MgO boards, [Company Name], a leading manufacturer of construction materials, has introduced a state-of-the-art High Efficient MgO Board Making Machine that is set to revolutionize the production of MgO boards.The High Efficient MgO Board Making Machine, developed by [Company Name], utilizes advanced technology and innovative processes to ensure the efficient and high-quality production of MgO boards. The machine is designed to significantly increase the output of MgO boards while maintaining the highest standards of quality and reliability. This breakthrough technology is poised to transform the construction industry by providing a sustainable and cost-effective solution for building materials.With the ability to produce MgO boards of various sizes and specifications, the High Efficient MgO Board Making Machine enables construction companies and manufacturers to meet the diverse needs of their projects. Whether it's for residential, commercial, or industrial applications, the machine offers unparalleled flexibility and efficiency in the production of MgO boards.The introduction of this cutting-edge machine underscores [Company Name]'s commitment to innovation and sustainability in the construction industry. With a strong focus on research and development, [Company Name] has continuously invested in advanced technologies to enhance the performance and reliability of its products. The High Efficient MgO Board Making Machine is a testament to [Company Name]'s dedication to providing high-quality and eco-friendly building materials to its customers.In addition to its technological prowess, [Company Name] prides itself on its comprehensive customer support and service. The company offers training and technical assistance to ensure that its customers can maximize the potential of the High Efficient MgO Board Making Machine. This commitment to customer satisfaction sets [Company Name] apart as a reliable partner in the construction industry, empowering its clients to achieve their production goals efficiently and effectively.Furthermore, the introduction of the High Efficient MgO Board Making Machine reflects [Company Name]'s dedication to sustainability and environmental responsibility. By using MgO boards in construction, builders can reduce their carbon footprint and contribute to a greener future. The machine's efficient production processes also minimize waste and energy consumption, aligning with [Company Name]'s commitment to sustainable manufacturing practices.The High Efficient MgO Board Making Machine is a game-changer for the construction industry, offering a cost-effective, eco-friendly, and high-performance solution for building materials. With its innovative technology and robust capabilities, the machine is poised to elevate the production of MgO boards and meet the growing demand for sustainable construction materials.As [Company Name] continues to lead the way in the development of advanced construction technologies, the High Efficient MgO Board Making Machine stands as a testament to the company's unwavering dedication to innovation and excellence. By bringing this groundbreaking machine to the market, [Company Name] is driving positive change in the construction industry and empowering builders to construct with confidence and efficiency.With the High Efficient MgO Board Making Machine, [Company Name] is not only shaping the future of construction but also setting new standards for quality, sustainability, and performance in the industry. The machine's impact is poised to be felt across the construction landscape, ushering in a new era of efficient and eco-friendly building materials.

Read More

High-Quality Fiber Optic Star Ceiling Panels for Moon Shooting - FCC Approved, 15W Power, 600*600mm Size

China is known for its phenomenal innovation and technological advancements. In recent times, it has been making immense strides with the production of high-quality PMMA 15W Fiber Optic Star Ceiling Panels 600*600mm FCC for moon shooting. These products are second to none with their excellent quality and strict quality control.Leading Fiber Optic Star Ceiling Panels factories have been working tirelessly to ensure that their products meet the high standards of tech enthusiasts and professionals in the industry. With this, they have been producing highly efficient and reliable PMMA 15W Fiber Optic Star Ceiling Panels, designed specifically for moon shooting.The star ceiling panels are rated 15W and are made from Polymethyl methacrylate (PMMA), a highly durable and versatile material that is commonly used to produce high-tech products. The panels are excellent for providing accurate and reliable fiber optic lighting without the need for electricity, making them an eco-friendly lighting solution.The PMMA 15W Fiber Optic Star Ceiling Panels have been particularly successful in moon shooting projects, where the clarity and accuracy of the lighting are critical. They produce a stunning starlight effect that is ideal for creating the illusion of a starry sky, perfect for filming and photography.One of the greatest advantages of using these star ceiling panels is the fact that they do not emit any heat, making them an ideal solution for sensitive lighting projects, such as those required in the filming or photography industry. In addition, the PMMA material used in their production ensures that they are highly durable and long-lasting.China's leading Fiber Optic Star Ceiling Panels product market has been at the forefront of innovating and producing top-quality star ceiling panels, among other high-tech products. With their neck for excellence and their focus on maintaining strict quality control, they have managed to establish themselves as market leaders, providing clients with reliable and efficient products for their lighting needs.In conclusion, PMMA 15W Fiber Optic Star Ceiling Panels 600*600mm FCC for moon shooting from China are some of the most innovative and reliable lighting solutions on the market today. Their high-quality production and strict quality control ensure that they are long-lasting and efficient, making them the perfect fit for any sensitive lighting project. Well done, China, for yet another remarkable achievement in the technological world.

Read More

Affordable PVC Laminated Gypsum Board Machine: A Budget-friendly Option

Read More

Fiberboard Plant in Diboll Shut Down, Resulting in Job Loss for 90 Workers

The recent closure of a fiberboard plant in Diboll, Texas has caused a major impact on its 90 employees. While the reasons for the plant's shutdown may not be clear, it highlights the complexity of the manufacturing industry. As businesses grow and expand, they are likely to face challenges along the way, which may include fluctuations in demand, regulatory changes, and financial pressures.Despite this, there continues to be a demand for fiberboard products that are used in construction, furniture making, and other industries. Fortunately, there are many mineral fiber board machine factories that provide high-quality products for these sectors.If you are in the market for fiberboard products or are looking to start a manufacturing business, it is essential to partner with a reliable and reputable mineral fiber board machine factory. With that in mind, here are some of the best mineral fiber board machine factories to consider.1. Hebei Lvjoe Machinery Manufacturing Co., Ltd.Hebei Lvjoe Machinery Manufacturing Co., Ltd. is a professional manufacturer of mineral fiber board machines, gypsum board production lines, and other building material machinery. The factory has over 20 years of experience in the industry and has exported its products to more than 50 countries around the world.One of the things that make Hebei Lvjoe exceptional is its commitment to quality control. The factory uses advanced equipment and tools to ensure that the products that they produce meet the highest standards. Additionally, they have an experienced team of engineers and technicians who provide technical support to their clients.2. Shandong Chuangxin Building Materials Complete Equipment Co., Ltd.Shandong Chuangxin Building Materials Complete Equipment Co., Ltd. is another top mineral fiber board machine factory that specializes in the production of gypsum board equipment and mineral wool board equipment. The factory's products are used in the construction and decoration industries.The factory has a modern production facility that houses advanced equipment, including CNC machines, press brakes, and welding machines. They also have a team of highly skilled professionals who are dedicated to providing the best services to their clients.3. Wuxi Suhang Machinery Manufacturing Co., Ltd.Wuxi Suhang Machinery Manufacturing Co., Ltd. is a leading manufacturer of mineral fiber board machines, metal roll forming machines, and other construction machinery. The factory has a strong focus on research and development and has invested heavily in new technology to improve its production processes.The factory's products are known for their quality and durability, and they come with a one-year warranty. They also offer excellent after-sales support, including technical assistance and spare parts supply.In conclusion, the recent closure of the fiberboard plant in Diboll serves as a reminder of the importance of partnering with reputable mineral fiber board machine factories. By doing so, you can be confident that you are getting high-quality products that meet your needs and standards. Hebei Lvjoe Machinery Manufacturing Co., Ltd., Shandong Chuangxin Building Materials Complete Equipment Co., Ltd., and Wuxi Suhang Machinery Manufacturing Co., Ltd. are some of the best factories that you can consider for your requirements.

Read More

Top Factories for Quality Gypsum Ceiling Pressing Machines

Title: Revolutionizing Gypsum Ceiling Production: Cutting-edge Pressing Machine Factories Challenge Industry StandardsIntroduction:The global demand for high-quality gypsum ceilings has been on the rise, prompting manufacturers to explore innovative technologies to meet the increasing needs of the market. Several pioneering companies have stepped up, establishing themselves as leaders in the realm of gypsum ceiling pressing machines. In this article, we will delve into some of the best gypsum ceiling pressing machine factories, highlighting their contributions and commitment to revolutionizing the industry.Gypsum Ceiling Pressing Machine Factory A:One of the leading players in the industry, Factory A, has gained a formidable reputation for its breakthrough technologies and commitment to quality. With state-of-the-art facilities, Factory A has revolutionized the gypsum ceiling production process, streamlining efficiency while maintaining exceptional standards. By employing advanced automation and precision engineering, the factory assures optimal performance of their pressing machines, resulting in flawless, finely finished gypsum ceiling panels.Moreover, Factory A's dedication to sustainability is commendable. They have implemented eco-friendly measures throughout their manufacturing process, such as recycling and minimizing waste generation. The factory's adherence to sustainable practices underscores their commitment to creating a greener future for the construction industry.Gypsum Ceiling Pressing Machine Factory B:Factory B has carved a niche for itself by consistently delivering cutting-edge gypsum ceiling pressing machines. Recognized for their attention to detail and continuous innovation, this factory has successfully impressed industry experts and customers alike. Engineers at Factory B have developed pressing machines that leverage advanced computerized technology, ensuring unparalleled accuracy and precision.In addition to their technological expertise, Factory B prioritizes customer satisfaction. By working closely with their clients, the factory ensures that their machines are tailored to meet specific requirements and optimize production processes. This customer-centric approach has allowed Factory B to build lasting relationships and maintain a loyal customer base.Gypsum Ceiling Pressing Machine Factory C:Factory C has earned its place among the best gypsum ceiling pressing machine factories due to its relentless pursuit of excellence. Notably, the factory's state-of-the-art research and development division constantly strives to innovate machinery to enhance efficiency and convenience. Through extensive market research and collaboration with industry leaders, Factory C consistently introduces groundbreaking features that set new benchmarks in gypsum ceiling production.Furthermore, Factory C emphasizes the importance of quality control throughout the manufacturing process. Every machine undergoes rigorous testing to ensure exceptional performance and durability. This commitment to uncompromising quality has positioned Factory C as a reliable and preferred choice for gypsum ceiling manufacturers worldwide.Conclusion:The gypsum ceiling pressing machine factories mentioned above, Factory A, Factory B, and Factory C, represent the pinnacle of innovation and quality in the industry. Their dedication to advanced technology, sustainability, customer satisfaction, and stringent quality control sets them apart from their competitors. These factories continue to challenge industry standards through their continuous pursuit of excellence, revolutionizing the gypsum ceiling production landscape. As the demand for high-quality gypsum ceilings continues to grow, manufacturers can rely on these factories to provide them with state-of-the-art pressing machines, ensuring a bright future for the industry.

Read More