Top Quality Gypsum Ceiling Tiles Machine for Sale - A Complete Guide

By:Admin

With a strong focus on innovation and quality, {} has positioned itself as a go-to source for manufacturers looking to upgrade their production facilities. The company's expertise in gypsum ceiling tiles machine technology is backed by years of experience and a dedication to meeting the evolving demands of the industry. Their commitment to excellence has made them a trusted partner for businesses seeking reliable and efficient machinery for their operations.

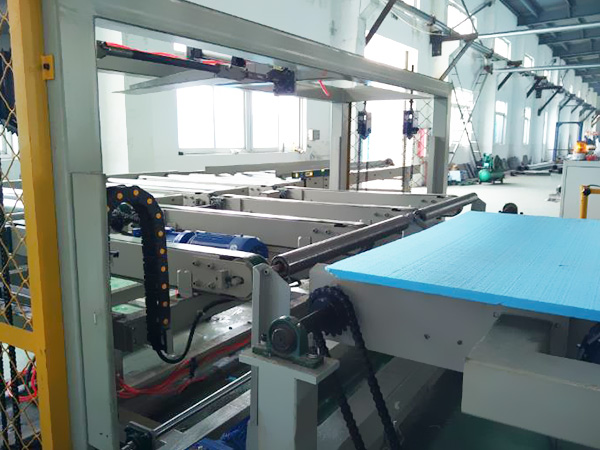

{}'s gypsum ceiling tiles machine is designed to deliver exceptional performance and precision. The state-of-the-art technology employed in their machines ensures that manufacturers can produce high-quality ceiling tiles with ease. From cutting and shaping to finishing and packaging, {}'s machines are built to streamline the production process and maximize efficiency.

One of the key features of {}'s gypsum ceiling tiles machine is its versatility. The machine is capable of producing a wide range of ceiling tile designs, allowing manufacturers to cater to diverse customer preferences. Whether it's plain, patterned, or textured tiles, {}'s machine can handle the task with ease, making it a cost-effective solution for businesses looking to expand their product offerings.

In addition to its technical prowess, {}'s gypsum ceiling tiles machine is also lauded for its user-friendly interface. The intuitive controls and automation features make it easy for operators to oversee the production process and make adjustments as needed. This not only saves time but also minimizes the risk of errors, resulting in consistent and reliable output.

Furthermore, {} offers comprehensive support and maintenance services for their gypsum ceiling tiles machine. Their team of experts is readily available to provide technical assistance and troubleshooting, ensuring that manufacturers can keep their production running smoothly at all times. This commitment to after-sales service further solidifies {}'s reputation as a trusted partner in the industry.

With an extensive client base that spans across the globe, {} has established itself as a leading provider of gypsum ceiling tiles machines. Their machines have been deployed in numerous manufacturing facilities, delivering outstanding results and driving efficiency for their clients. The testimonials from satisfied customers stand as a testament to the quality and reliability of {}'s products.

As the demand for high-quality ceiling tiles continues to grow, it is essential for manufacturers to invest in top-notch machinery to stay ahead in the market. {}'s gypsum ceiling tiles machine offers a compelling solution for businesses seeking to elevate their production capabilities and meet the evolving needs of their customers. With a track record of excellence and a commitment to innovation, {} is poised to remain a frontrunner in the gypsum ceiling tiles machine industry for years to come.

Company News & Blog

Fiberboard Insulation Developer Advances Plans to Convert Closed Paper Mill into Production Facility

A Maine-based startup company is set to take a significant step forward in the world of green building, as it plans to convert a closed paper mill into a new production facility for fiberboard insulation.The company behind the project has become known for its innovative approach to creating sustainable insulation materials, and its new facility represents a major milestone for both the company and the green building industry as a whole.Fiberboard insulation is a type of insulation made from wood fibers, usually combined with a resin binder. This type of insulation is known for its excellent thermal insulation properties and resistance to moisture, making it an ideal choice for use in buildings, especially those in colder climates.The new production facility will be located in the town of Millinocket, Maine, and will be capable of producing up to 100 million square feet of fiberboard insulation each year. This is a significant increase from the company's existing production capacity, and will allow it to meet growing demand for its products from around the world.According to the company's CEO, the new facility will be equipped with state-of-the-art production equipment, designed to ensure the highest levels of quality and efficiency. Additionally, the company plans to invest in innovative new technologies and processes to further improve the sustainability and environmental performance of its insulation products.The company's fiberboard insulation products are already highly regarded within the green building industry, thanks to their superior performance and eco-friendly credentials. The insulation is made from 100% recycled and reclaimed wood fibers, making it a highly sustainable and renewable material.Furthermore, the company's products are free from harmful chemicals and additives, making them an excellent choice for those with allergies or sensitivities to traditional insulation materials. This is a particularly important consideration for those building or renovating homes or commercial buildings in urban areas, where indoor air quality is a major concern.The CEO of the company, speaking about the new production facility, said: "This is a major milestone for our company and for the green building industry as a whole. We are excited to be bringing our innovative approach to insulation production to a wider audience, and to be able to meet growing demand for sustainable and eco-friendly building materials."The new production facility is expected to create a significant number of new jobs in the local area, providing a welcome boost to the local economy. Additionally, the company's commitment to sustainability and environmental responsibility is expected to have a positive impact on the wider community, both in terms of the materials it produces and the innovative technologies it develops.Overall, this is an exciting development for the green building industry, and one which is sure to be closely watched by those working in the field. With demand for sustainable building materials continuing to grow, the new production facility is a positive step towards a more sustainable and eco-friendly built environment.

Affordable Mgo Board Making Machine: A Complete Pricelist

Today, we are excited to introduce a new Mgo Board Making Machine that is set to revolutionize the construction industry. The Mgo Board Making Machine is a versatile and efficient piece of equipment that is designed to produce high-quality magnesium oxide boards for various construction applications. The machine is engineered to provide superior performance, speed, and precision, making it an essential addition to any construction operation.The Mgo Board Making Machine offers a wide range of benefits that make it a valuable asset for any construction business. The machine is capable of producing Mgo boards of various sizes and thicknesses, allowing for versatility in construction projects. Additionally, the machine is equipped with advanced technology that ensures uniform board density and smooth surface finish, resulting in superior quality boards that meet industry standards.In terms of efficiency, the Mgo Board Making Machine is designed to optimize production processes, minimize material waste, and reduce labor costs. The machine features a user-friendly interface and automated controls that enable easy operation and monitoring of the production process. This enables construction companies to increase their productivity and meet project deadlines with ease.Furthermore, the Mgo Board Making Machine is built to be durable and reliable, ensuring long-term performance and minimal maintenance requirements. The machine is constructed with high-quality materials and components, and it undergoes stringent quality testing to guarantee its reliability and longevity. This means that construction businesses can rely on the Mgo Board Making Machine to deliver consistent results and minimize downtime.The introduction of the Mgo Board Making Machine is a significant milestone for our company. We are dedicated to providing innovative solutions that empower construction businesses to thrive in today's competitive market. The Mgo Board Making Machine reflects our commitment to delivering high-performance equipment that meets the evolving needs of the construction industry.As a leading manufacturer (), we have a strong track record in developing cutting-edge machinery that enhances construction processes. Our team of experienced engineers and technicians has worked tirelessly to design and create the Mgo Board Making Machine, ensuring that it meets the highest standards of quality, performance, and reliability. We are confident that the machine will make a positive impact on construction operations and contribute to the success of our customers.In conclusion, the Mgo Board Making Machine is a game-changer for the construction industry. Its advanced technology, efficiency, and reliability make it an essential investment for construction businesses looking to enhance their production capabilities and deliver high-quality results. With the introduction of this innovative machine, we are proud to continue our legacy of excellence in providing industry-leading solutions for the construction sector.For more information about the Mgo Board Making Machine and its pricing, please contact us at () or visit our website at (). We look forward to assisting you in integrating this groundbreaking machine into your construction operations and helping you achieve your business goals.

Affordable WPC Door Board Production Machine - PE Profile Extrusion Line Introduction PE profiles are commonly used in windows, wall panels, and decorative applications. This extrusion line offers an ideal solution for producing these profiles. The line comprises a conical twin-screw extruder, mould, calibration table, hauler, cutter, and stacker. Moreover, for PE window profiles, the line includes a co-extruder.

In the world of extrusion machines, JEEBO Machinery is a name that stands out for their precision and quality. If you're looking for a reliable and efficient PVC PE profile extrusion line, then JEEBO Machinery's Factory Cheap Hot Wpc Door Board Making Machine is the perfect choice.PVC profiles are in high demand for creating windows, wall panels, and small decorative profiles. With the Factory Cheap Hot Wpc Door Board Making Machine, you can produce all these profiles with ease. This machine is manufactured with top-of-the-line conical twin screw extruders, moulds, calibration tables, haulers, cutters, and stackers to ensure the best quality output.The extruder is the core component that handles the PVC material and transforms it into the desired shape and size. With JEEBO Machinery's conical twin screw extruder, you'll get superior results and efficient processing speeds. The machine's precision mould ensures that every product comes out uniformly and meets the required specifications.Once the profile is formed, it needs to be cooled and calibrated before being cut into the required size. JEEBO Machinery's calibration table gives you full control over the cooling process, resulting in a proper shape and size. The hauler moves the profile through the machine with precision and accuracy, while the cutter ensures that the final product is accurately sized. The stacker collects the finished product in an organized manner, making the packaging and transportation process smooth and seamless.JEEBO Machinery's Factory Cheap Hot Wpc Door Board Making Machine is not only efficient, but it also offers high-quality output at an affordable price. The machine is also versatile enough to handle PVC material with or without brand names. In addition, JEEBO Machinery's Cheap Xps Foam Board Extrusion Line is an excellent choice for producing foam boards. This machine is easy to operate, efficient, and produces high-quality foam board extrusions that meet the required standards. The machine is easy to maintain and is built with durable and long-lasting materials, making it an excellent investment for your business.In conclusion, JEEBO Machinery is a reputable and trustworthy company that produces reliable and efficient extrusion machines. If you're looking for a premium PVC PE profile extrusion line or a cheap XPS foam board extrusion line, JEEBO Machinery has got you covered. With their quality and affordable products, you can rest assured that your business is in good hands.

Affordable and Lightweight Yarn Recommendations for a Warm Winter Shawl

article focusing on affordable and lightweight yarn options for winter knitting projects.)Winter is the perfect season for knitting cozy shawls, scarves and blankets. But when it comes to choosing the right yarn for the project, many knitters face a dilemma. On one hand, you want a material that will keep you warm and snug, but on the other hand, you don't want it to be too heavy or expensive. The good news is that there are plenty of affordable and lightweight yarn options to choose from, as we explore in this article.Merino WoolOne of the most popular options for winter knitting is merino wool. This soft and warm yarn is made from the wool of merino sheep, known for their fine fleece. Merino wool is lightweight and breathable, making it ideal for layering and wearing indoors. It also has natural moisture-wicking properties, which means it will keep you dry and comfortable. Although merino wool can be on the pricier side, it's worth investing in for its durability and versatility.Acrylic YarnFor those looking for a more affordable option, acrylic yarn is a great choice. This man-made fiber is lightweight, easy to wash and available in a wide variety of colors and textures. Acrylic yarn is also hypoallergenic, making it a great option for those with sensitive skin. While it may not be as warm as some other fibers, it's a great option for layering or for wearing in milder winter weather.Alpaca YarnAlpaca yarn is another excellent option for winter knitting. This soft and insulating fiber comes from the fleece of the alpaca, a South American animal that's related to the llama. Alpaca yarn is incredibly warm and lightweight, making it ideal for winter accessories like scarves and hats. It is also hypoallergenic and comes in a variety of natural shades. While it can be more expensive than some other fibers, it's worth the investment for its warmth and comfort.Cotton YarnWhile many knitters associate cotton yarn with warm weather projects, it can also be a great option for winter knitting. Cotton is lightweight and breathable, making it ideal for layering or wearing indoors. It's also a more affordable option than some other fibers. While cotton may not be as warm as wool or alpaca, it's a great option for those who prefer natural fibers and want to avoid itchiness and irritation that can come from other materials.Bamboo YarnFinally, bamboo yarn is a great option for those looking for a lightweight and eco-friendly material. Bamboo is a sustainable and renewable resource, and bamboo yarn is incredibly soft and comfortable. It's also naturally antibacterial and hypoallergenic, making it a great option for those with sensitive skin. While it may not be as warm as other fibers, it's a great option for layering or for warmer winter weather.In conclusion, when it comes to finding the right yarn for your winter knitting project, there are plenty of affordable and lightweight options to choose from. Whether you prefer natural fibers like wool and alpaca, or man-made fibers like acrylic and bamboo, there's a yarn out there that's perfect for your needs. So stock up on your favorite materials and get ready to create cozy and stylish accessories to keep you warm all winter long.

Top Quality Gypsum Ceiling Tiles Machine for Sale - A Complete Guide

The gypsum ceiling tiles machine industry is a key player in the construction and interior design sector. With the demand for high-quality ceiling tiles on the rise, it is imperative for manufacturers to invest in top-of-the-line machinery to meet the needs of their clients. In this regard, {} has emerged as a leader in providing the best gypsum ceiling tiles machine in the market.With a strong focus on innovation and quality, {} has positioned itself as a go-to source for manufacturers looking to upgrade their production facilities. The company's expertise in gypsum ceiling tiles machine technology is backed by years of experience and a dedication to meeting the evolving demands of the industry. Their commitment to excellence has made them a trusted partner for businesses seeking reliable and efficient machinery for their operations.{}'s gypsum ceiling tiles machine is designed to deliver exceptional performance and precision. The state-of-the-art technology employed in their machines ensures that manufacturers can produce high-quality ceiling tiles with ease. From cutting and shaping to finishing and packaging, {}'s machines are built to streamline the production process and maximize efficiency.One of the key features of {}'s gypsum ceiling tiles machine is its versatility. The machine is capable of producing a wide range of ceiling tile designs, allowing manufacturers to cater to diverse customer preferences. Whether it's plain, patterned, or textured tiles, {}'s machine can handle the task with ease, making it a cost-effective solution for businesses looking to expand their product offerings.In addition to its technical prowess, {}'s gypsum ceiling tiles machine is also lauded for its user-friendly interface. The intuitive controls and automation features make it easy for operators to oversee the production process and make adjustments as needed. This not only saves time but also minimizes the risk of errors, resulting in consistent and reliable output.Furthermore, {} offers comprehensive support and maintenance services for their gypsum ceiling tiles machine. Their team of experts is readily available to provide technical assistance and troubleshooting, ensuring that manufacturers can keep their production running smoothly at all times. This commitment to after-sales service further solidifies {}'s reputation as a trusted partner in the industry.With an extensive client base that spans across the globe, {} has established itself as a leading provider of gypsum ceiling tiles machines. Their machines have been deployed in numerous manufacturing facilities, delivering outstanding results and driving efficiency for their clients. The testimonials from satisfied customers stand as a testament to the quality and reliability of {}'s products.As the demand for high-quality ceiling tiles continues to grow, it is essential for manufacturers to invest in top-notch machinery to stay ahead in the market. {}'s gypsum ceiling tiles machine offers a compelling solution for businesses seeking to elevate their production capabilities and meet the evolving needs of their customers. With a track record of excellence and a commitment to innovation, {} is poised to remain a frontrunner in the gypsum ceiling tiles machine industry for years to come.

Fully Automatic PVC Film Gypsum Ceiling Board Lamination Machine: The Best Option for Your Business

In the fast-paced world of manufacturing, innovation and efficiency are key factors in staying ahead of the competition. With the increasing demand for high-quality PVC film gypsum ceiling board lamination machines, (Brand Name Removed) has introduced the best fully automatic machine to meet the needs of the industry.The (Brand Name Removed) fully automatic PVC film gypsum ceiling board lamination machine is a game-changer in the industry. It is designed to provide a seamless and efficient process for laminating PVC film onto gypsum ceiling boards. This machine is specifically engineered to handle the complexities of the lamination process with precision and accuracy, ensuring a high-quality end product every time.One of the key features of this machine is its fully automatic operation. This means that the entire lamination process is carried out without the need for manual intervention, reducing the possibility of errors and ensuring a consistent and uniform lamination across all boards. This level of automation not only improves efficiency but also minimizes the reliance on skilled labor, making it a cost-effective solution for manufacturers.Furthermore, the machine is equipped with advanced technology to ensure smooth and precise lamination. The control system is user-friendly and allows for easy adjustment of parameters to accommodate different board sizes and film thicknesses. This flexibility makes it suitable for a wide range of production needs, catering to the diverse requirements of the market.In addition to its technical capabilities, the (Brand Name Removed) fully automatic PVC film gypsum ceiling board lamination machine is also designed with durability in mind. The materials used in its construction are of the highest quality, ensuring a long lifespan and minimal maintenance requirements. This reliability is essential for manufacturers who depend on their machinery to operate continuously without costly downtime.As a leading manufacturer in the industry, (Brand Name Removed) is committed to providing not only top-of-the-line machinery but also exceptional customer service. The company's team of engineers and technical experts are always on hand to offer support and guidance, ensuring that their clients get the most out of their investment in the fully automatic PVC film gypsum ceiling board lamination machine.With a focus on innovation and quality, (Brand Name Removed) has established a solid reputation in the industry for delivering cutting-edge solutions that meet the evolving needs of manufacturers. The introduction of the best fully automatic PVC film gypsum ceiling board lamination machine is a testament to their dedication to advancing the industry and empowering their clients with state-of-the-art technology.In conclusion, the (Brand Name Removed) fully automatic PVC film gypsum ceiling board lamination machine sets a new standard for efficiency, precision, and reliability in the manufacturing of gypsum ceiling boards. Its advanced features and user-friendly design make it a standout choice for manufacturers looking to streamline their lamination process and produce high-quality end products. As the industry continues to evolve, (Brand Name Removed) remains at the forefront, driving innovation and empowering manufacturers to thrive in a competitive market.

Widely Utilized Iron Ore Gold Ore Crusher with CE Certification | Portable Diesel Engine Jaw Crusher Line 3" can be rewritten as: "Reliable and Efficient Jaw Crusher for Crushing Iron Ore and Gold Ore | CE Certified Portable Diesel Engine Jaw Crusher Line 3

Jaw Crusher - Your Ultimate Companion in CrushingJaw Crusher is a widely used crusher with a certification of CE and is preferred by many customers all over the world. This mechanical device is ideal for primary and secondary crushing operations and is capable of crushing material with a compression strength less than 320Mpa. The jaw crusher has a portable diesel engine, which makes it easy to move from one location to another.Features of Jaw CrusherThe jaw crusher has many features that make it a popular choice for crushing operations. Some of the key features of this machine are:1. High capacity and performance – The jaw crusher has a large capacity and is suitable for handling large quantities of materials. It can crush large rocks into smaller pieces, thereby reducing the time and effort required for crushing.2. Ease of operation – The jaw crusher is easy to operate and requires minimal maintenance. The machine is designed to be user-friendly, and the controls are simple and easy to understand.3. Versatile – The jaw crusher is versatile and can be used for a wide range of crushing applications. It is ideal for crushing hard and soft materials, including gold ore, iron ore, and gypsum.4. CE Certification – The jaw crusher comes with a certification of CE, which is an indication of its high-quality standards. This certification ensures that the machine is safe and reliable for use.Portable Diesel Engine Jaw Crusher LineThe portable diesel engine jaw crusher line is a durable and reliable solution for crushing materials in remote locations. The diesel engine provides power for the crusher, making it independent of external power sources. This makes the machine ideal for use in areas where there is no electricity supply.Mini Gypsum Cornice MachineMini Gypsum Cornice Machine is a popular product in the construction industry. This factory produces high-quality cornices that are used for decorative purposes. The machine is small, portable, and easy to operate, making it perfect for small-scale production.The machine is also highly versatile and can produce a wide range of cornices, including curved and straight designs. It is capable of producing cornices of various sizes and thicknesses, making it an ideal solution for a range of applications.ConclusionIn conclusion, Jaw Crusher is an excellent choice for primary and secondary crushing operations. With its high capacity, ease of operation, versatility, and CE certification, it is a reliable and efficient option for crushing materials. The portable diesel engine jaw crusher line is also a great solution for crushing materials in remote locations. The Mini Gypsum Cornice Machine is a valuable addition to any construction business, as it offers a cost-effective solution for producing high-quality cornices.

Lightweight Wall Panel Production Line for Mgo Board - Benefits and Cost Analysis

Jinan Zhongke Building Material Machinery Co., Ltd., a leading building material machinery manufacturer in China, has recently launched its latest Mgo Board Light Weight Wall Panel Production Line. The product line is designed to produce high-quality wall panels that are lightweight, fire-resistant, waterproof, and energy-efficient.The company has invested heavily in research and development to create a leading-edge Mgo Board Light Weight Wall Panel Production Line that is capable of producing wall panels of up to 3660mm*1220mm*3mm size at a rate of 1-30m/min. The production line is energy-efficient, cost-effective, and requires minimal labor for operation.According to the benefit analysis conducted by Jinan Zhongke Building Material Machinery Co., Ltd., the cost accounting for producing one wall panel includes raw material cost, water-electricity fee, and labor cost. The raw material cost for one panel is 15 yuan/piece, which is significantly lower than the price of traditional wall panels. The water-electricity fee is 0.2 yuan/piece, and the labor cost is 1.5 yuan/piece. Therefore, the total cost for one panel is 16.7 yuan/piece, which is much lower than the cost of traditional wall panels.Moreover, the Mgo Board Light Weight Wall Panel Production Line is fully automated, requiring only two workers for its operation. Thus, the labor cost is reduced, leading to higher profits for the manufacturers. The production line also has a low energy consumption rate, which reduces the overall manufacturing costs and is environmentally friendly.Jinan Zhongke Building Material Machinery Co., Ltd. is a reputable manufacturer that prioritizes customer satisfaction. The company has a team of experienced and professional engineers who provide customization services to meet the specific requirements of its clients.The Mgo Board Light Weight Wall Panel Production Line is suitable for manufacturing various types of lightweight wall panels, including partition walls, external walls, internal walls, and fire-resistant walls. The wall panels can be used in various residential and commercial buildings, such as hotels, schools, hospitals, and office complexes.In conclusion, Jinan Zhongke Building Material Machinery Co., Ltd.'s latest Mgo Board Light Weight Wall Panel Production Line is a revolutionary product that will transform the construction industry. It is cost-effective, energy-efficient, and produces high-quality wall panels that have numerous benefits over traditional wall panels. The product line's superior quality design, advanced technology, and customization services set it apart from its competitors, making it the go-to product for all lightweight wall panel needs.

High-Quality Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery from China's Leading Manufacturer

Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery: The Perfect Solution for Your Manufacturing NeedsThe world of manufacturing has evolved significantly in recent years. With the advent of new technologies, the process of producing goods has become more efficient, effective, and streamlined. One such technology that has gained immense popularity in recent years is the Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery. This cutting-edge equipment is the perfect solution for all your manufacturing needs and has revolutionized the industry in many ways.What is Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery?Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery is a state-of-the-art machinery used for manufacturing MgO board door cores and frames. This fully automated equipment is designed to produce high-quality MgO board door cores and frames with precision and accuracy. The machinery is equipped with advanced technology to ensure the highest standards of quality and performance. It is the perfect solution for businesses seeking to improve their manufacturing processes and increase their productivity levels.Features of Fully Automatic Mgo Board Door Core Frame Vacuum Forming MachineryThe Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery is designed with several features that make it a standout product. Some of its key features include:1. Fully Automated: The machinery is fully automated, which means it requires little or no human intervention during the manufacturing process. This feature ensures that the entire process is fast, efficient, and error-free.2. High-Quality Output: The machinery produces high-quality MgO board door cores and frames that meet industry standards. The equipment is designed to produce precise and accurate products that are of superior quality and durability.3. Cost-Effective: The Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery is a cost-effective solution for businesses seeking to improve their manufacturing processes. The machinery saves time, reduces waste, and minimizes production costs, making it a profitable investment for any business.4. Easy to Operate: The machinery is easy to operate, even for those with little or no experience in manufacturing. The user-friendly interface makes it easy to set up, operate, and maintain.Benefits of Fully Automatic Mgo Board Door Core Frame Vacuum Forming MachineryThe Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery offers numerous benefits to businesses seeking to improve their manufacturing processes. These benefits include:1. Increased Productivity: The machinery is designed to produce high-quality products quickly and efficiently, increasing productivity levels and reducing lead times.2. Cost Savings: The equipment saves businesses money by minimizing production costs associated with waste, labor, and maintenance.3. Improved Quality: The machinery produces high-quality products that meet industry standards, ensuring customer satisfaction and reducing product recalls.4. Better Control: The machinery provides better control over the manufacturing process, allowing for adjustments and modifications as needed.Mgo Board Forming Machine PricelistThe price of Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery varies depending on the manufacturer, model, and features. In general, the price ranges from $50,000 to $150,000. However, it is advisable to request a quote from the manufacturer for a more accurate price estimate.ConclusionThe Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery is the perfect solution for businesses seeking to improve their manufacturing processes and increase their productivity levels. With its advanced technology, high-quality output, and cost-effective features, the machinery offers numerous benefits to businesses of all sizes. If you are looking for a reliable and efficient solution for your manufacturing needs, consider investing in Fully Automatic Mgo Board Door Core Frame Vacuum Forming Machinery.